Constructor for industry

Industrial production places high demands on accuracy, flexibility and speed of development of technical solutions. Every day, enterprises produce assemblies, mechanisms, parts and equipment – both serial and individual, taking into account many variables: dimensions, loads, compatibility with other systems, safety regulations and industry standards. Any error at the stage of designing production equipment and products can lead to delays, budget overruns and failures in the production cycle. 2D and 3D constructors for industry – digital tools that automate the process of selecting, visualizing and calculating the cost of equipment – have become an effective solution to these risks.

AVADA MEDIA provides services for developing individual configurators, adapted to the technological features of a specific production. Our specialists combine deep expertise in industrial automation and modern approaches to interface and visualization development. Order an online constructor for industry to increase manageability, accuracy and business efficiency.

What are constructors for industry?

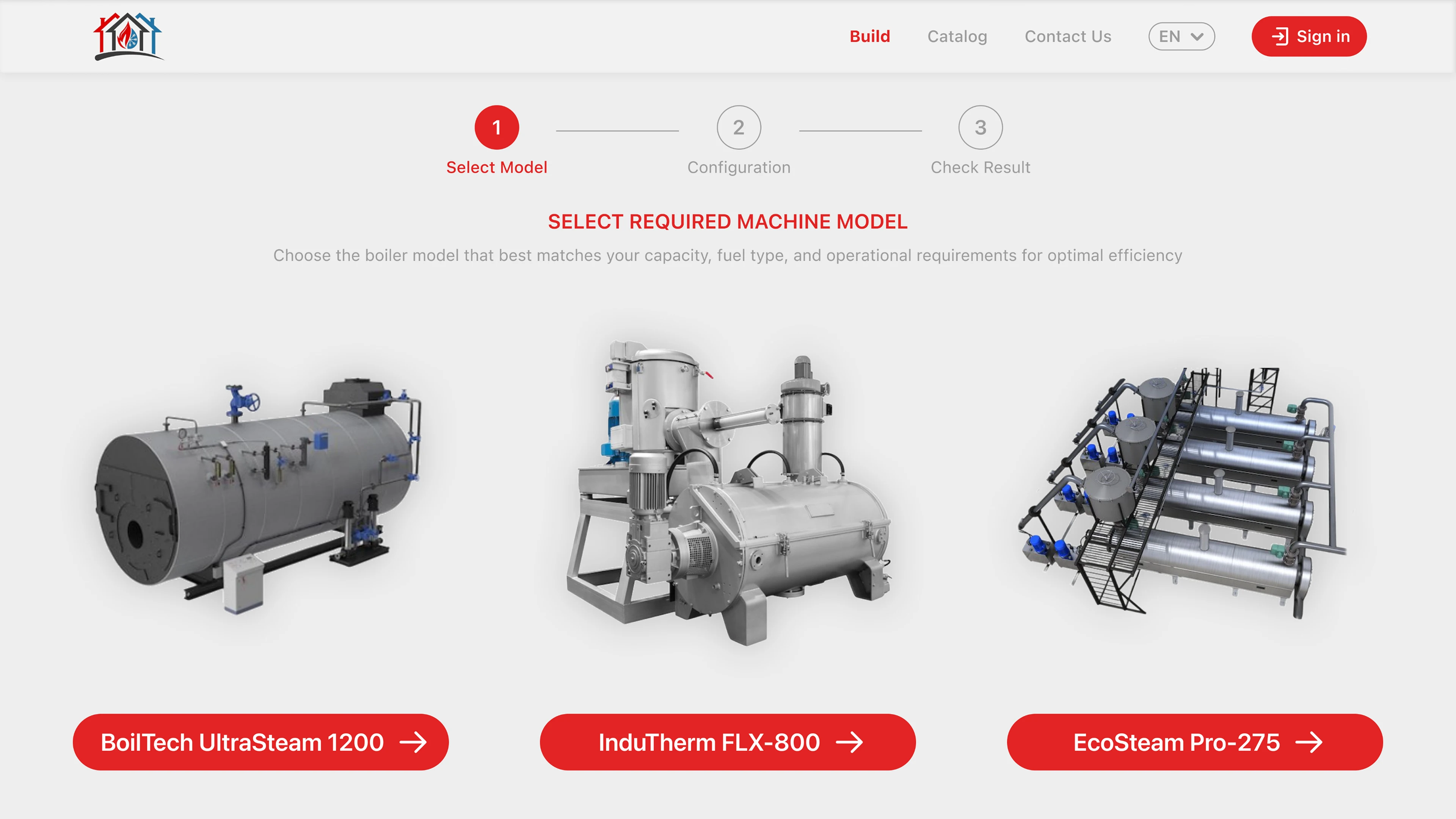

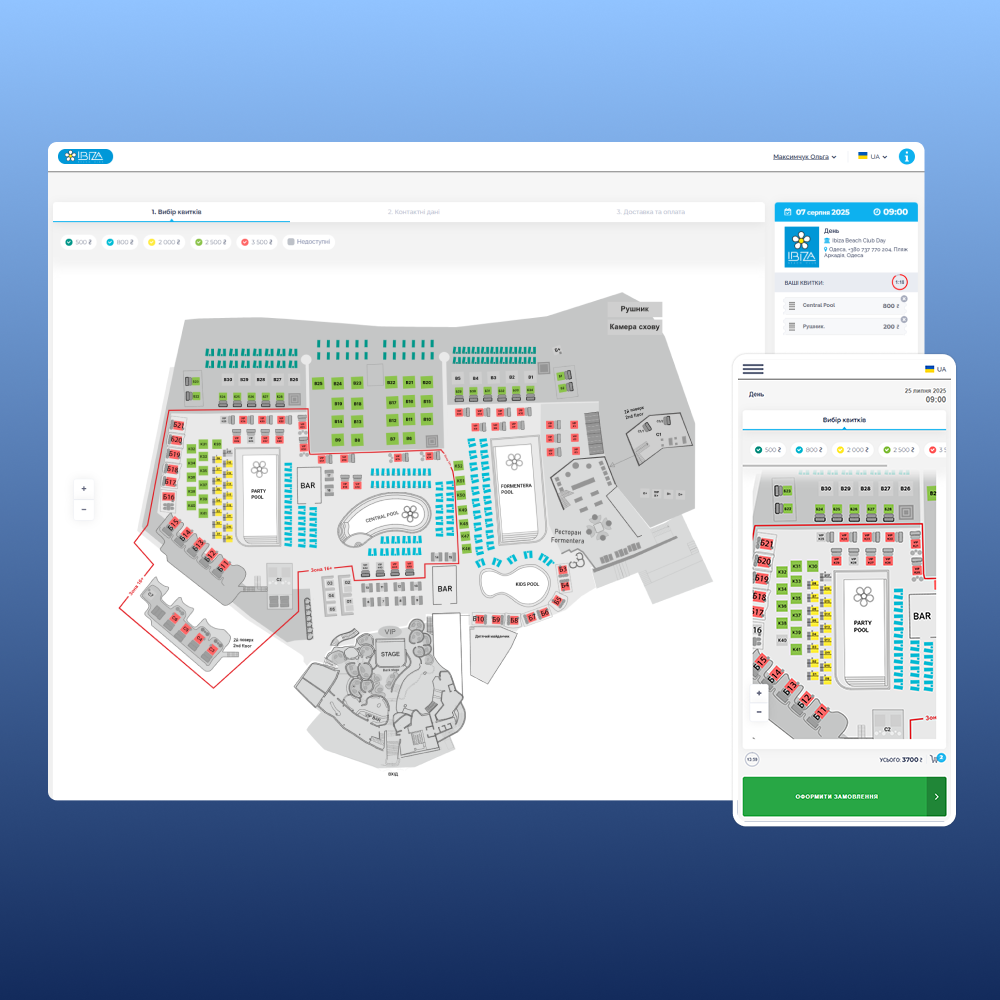

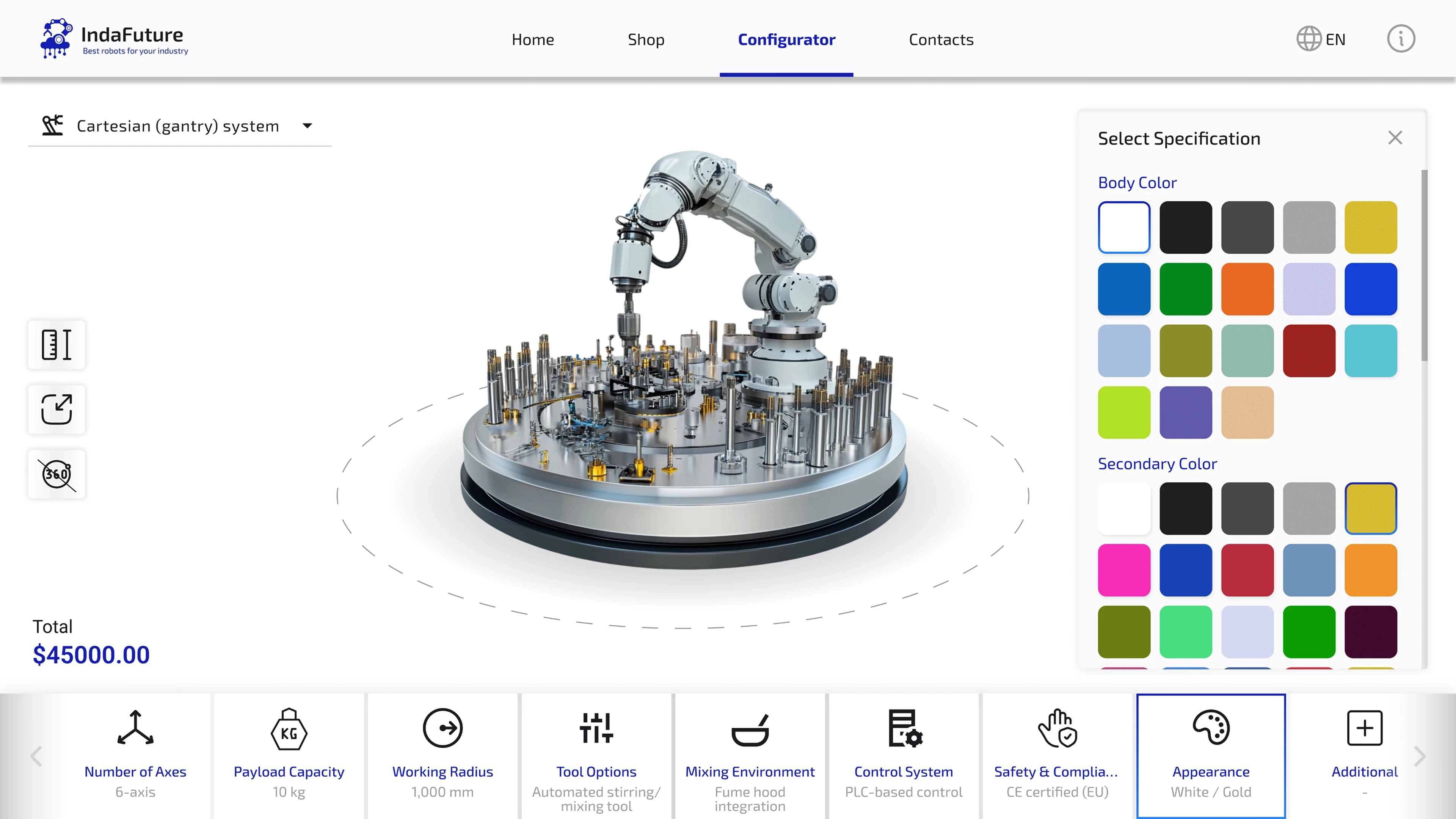

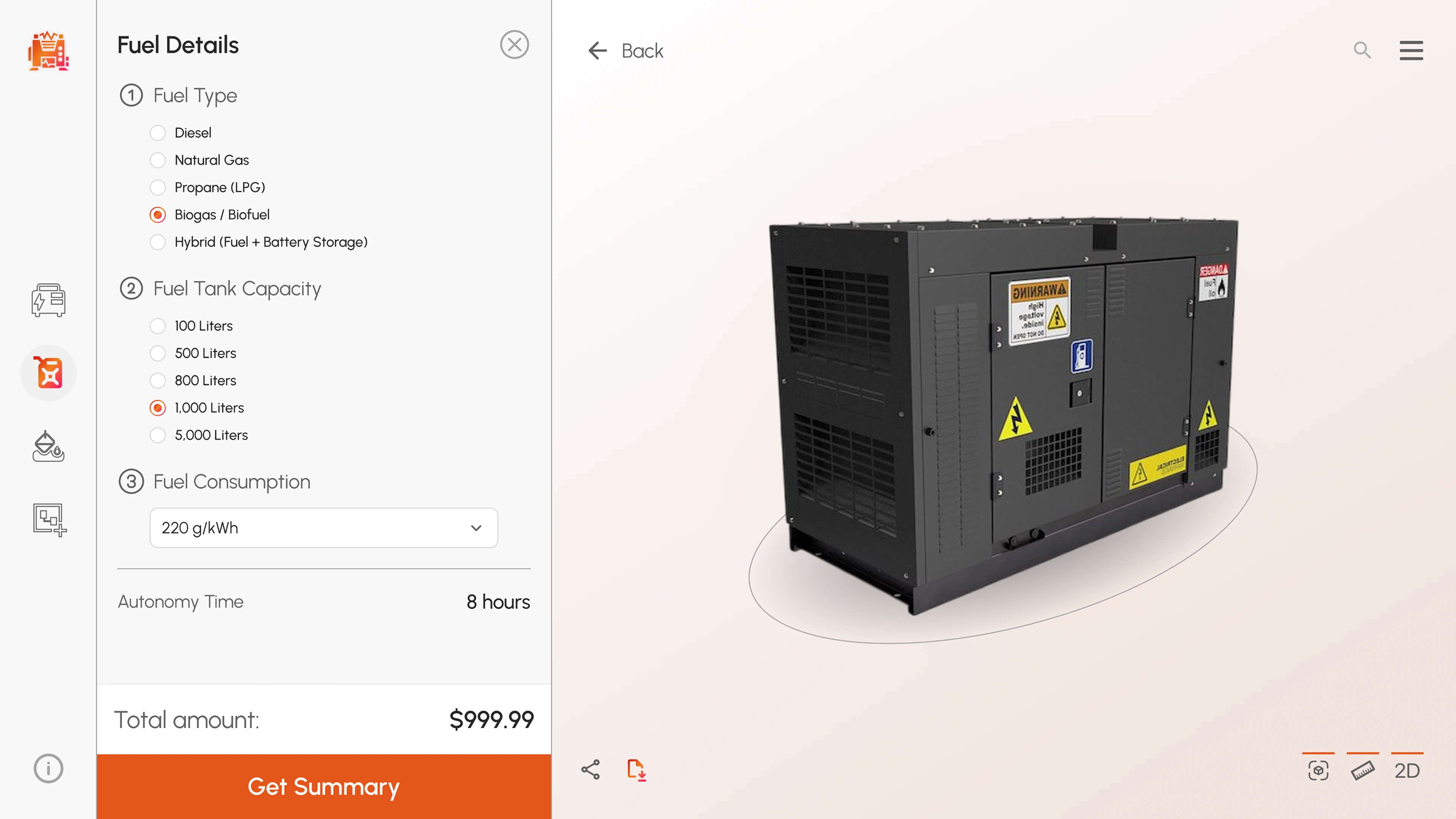

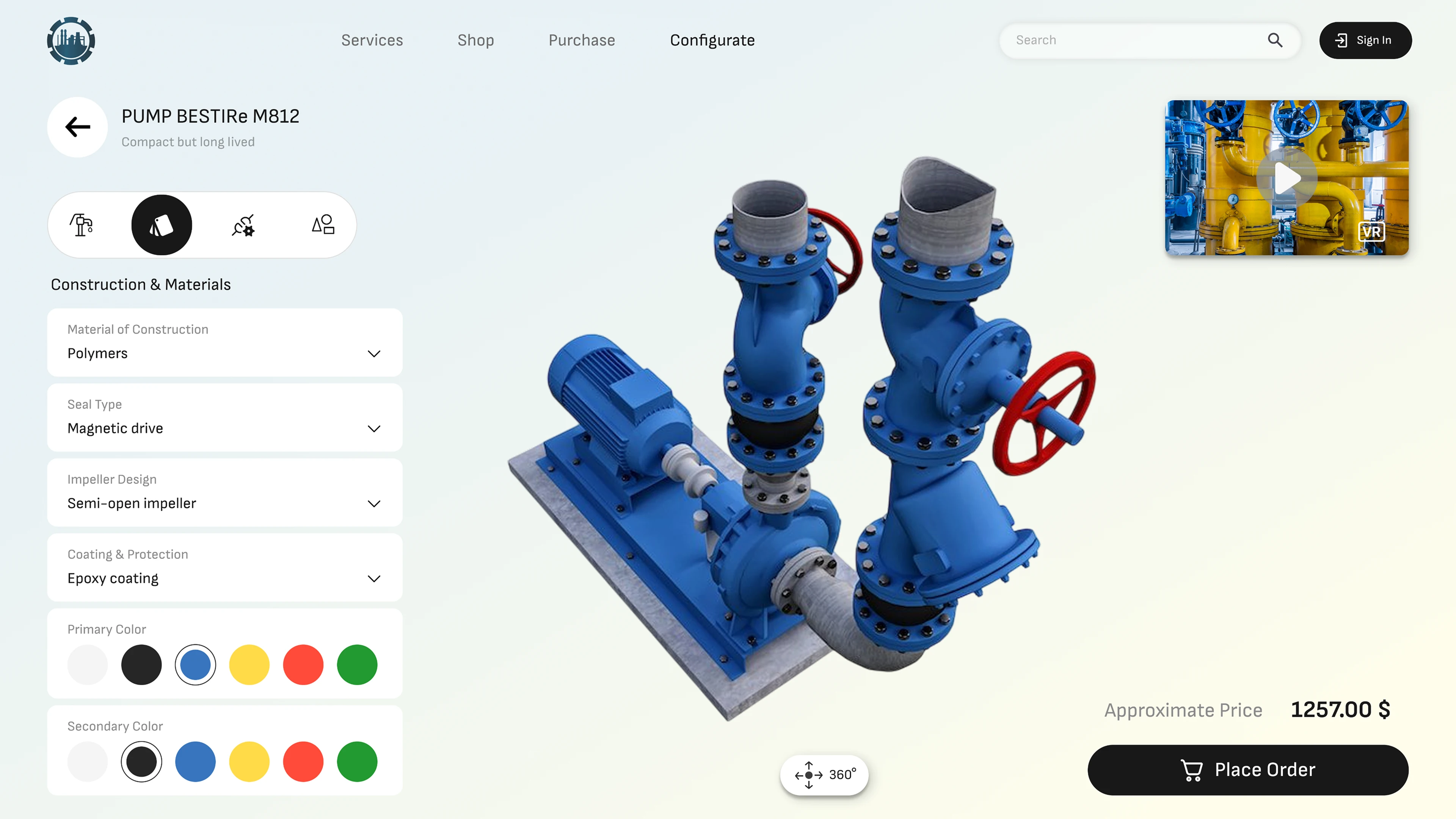

2D and 3D configurators for industrial production are custom software solutions for modeling and visualization of equipment based on specified parameters. In the interactive interface, the user can assemble a product from modules, set technical specifications, see the result in real time and receive a cost calculation, specification or technical task. They are used both at the pre-sale stage and within the production cycle, facilitating interaction between the client, manager, engineer and production department.

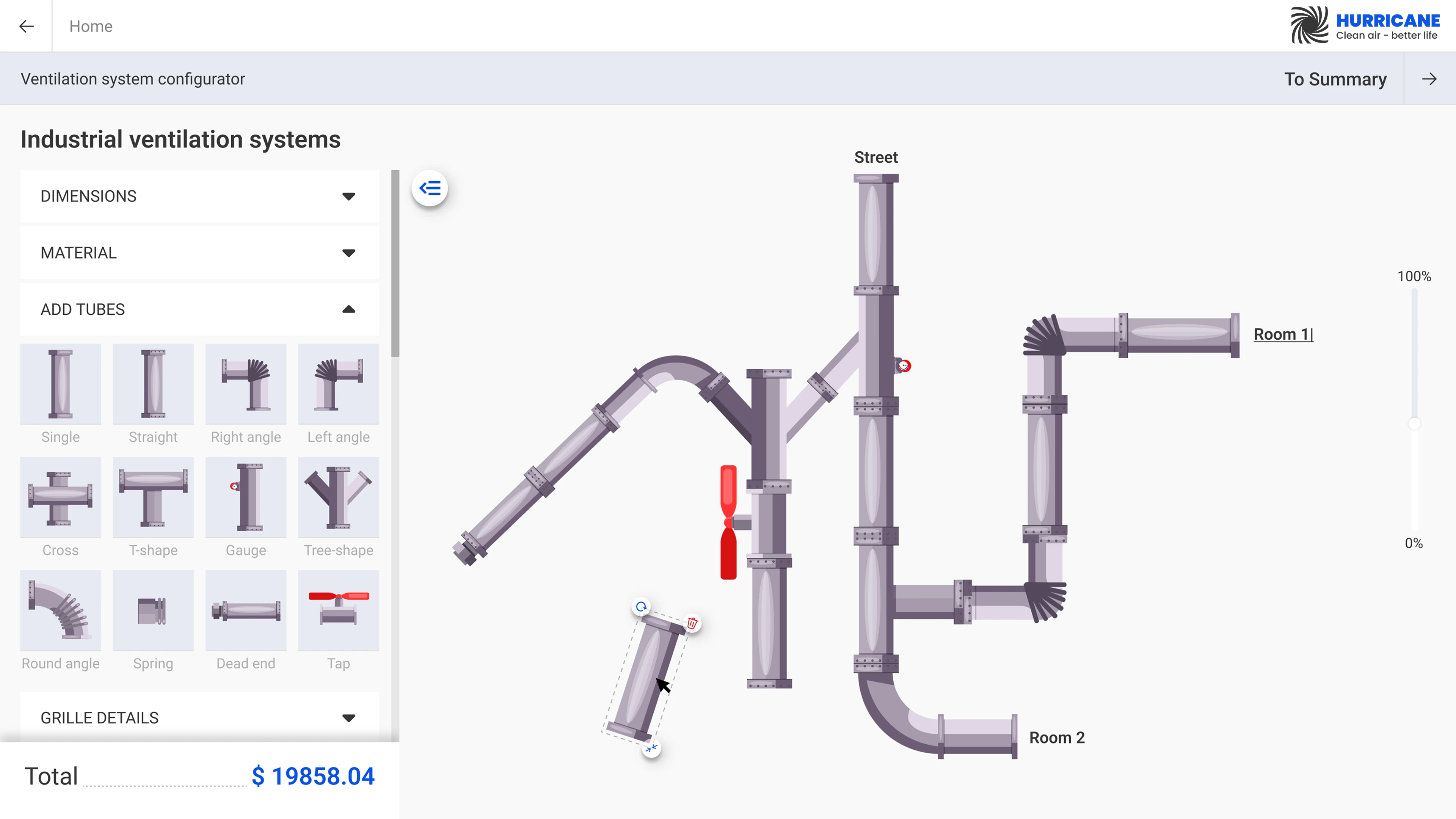

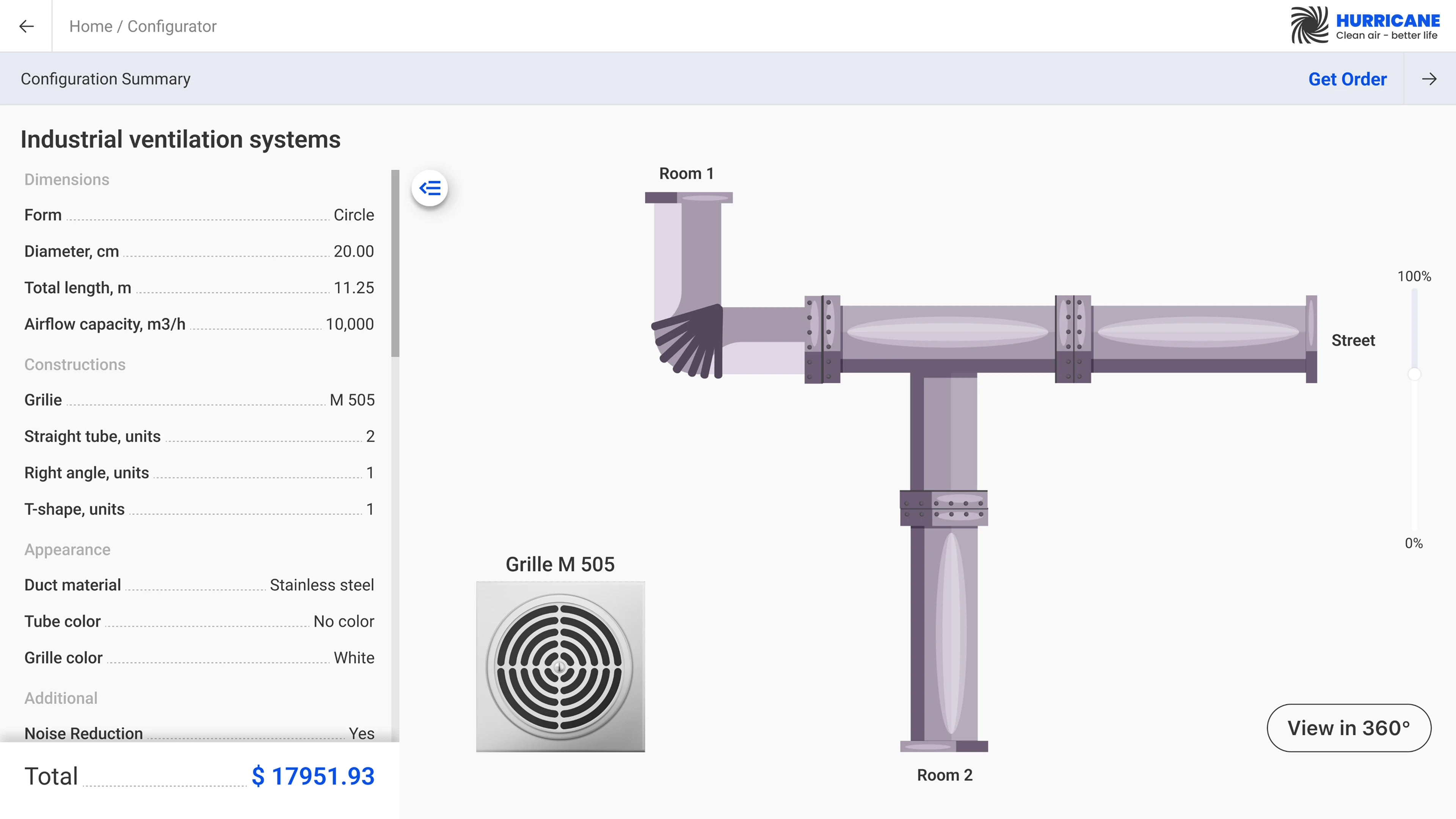

- 2D online constructor for industry is used to work with drawings, diagrams, and layouts - for example, when designing ventilation, electrical systems, furniture, and cutting materials.

- 3D online configurator of mechanisms and industrial products allows you to create three-dimensional parts and equipment with real-time visualization, component compatibility assessment and integration with CAD/CAM systems. It is an ideal tool for designing technological machines, equipment, machine tools, mechanisms, metal structures and other engineering solutions.

Implementing a constructor is especially effective in business areas where the product has many execution options, requires accurate technical calculations during assembly, the process of coordination with the customer takes a lot of time, and errors at the stage of order formation are costly.

Online industrial configurators have become a standard in mechanical engineering, metalworking, machine tool construction, the production of ventilation and electrical systems, modular structures, and other products with variable architecture.

Constructor functions for industrial production

Online configurators for industry are flexible systems that can handle complex parameters with engineering precision, take into account production constraints, and generate technical documentation. They can take on many important processes.

1. Accurate product modeling

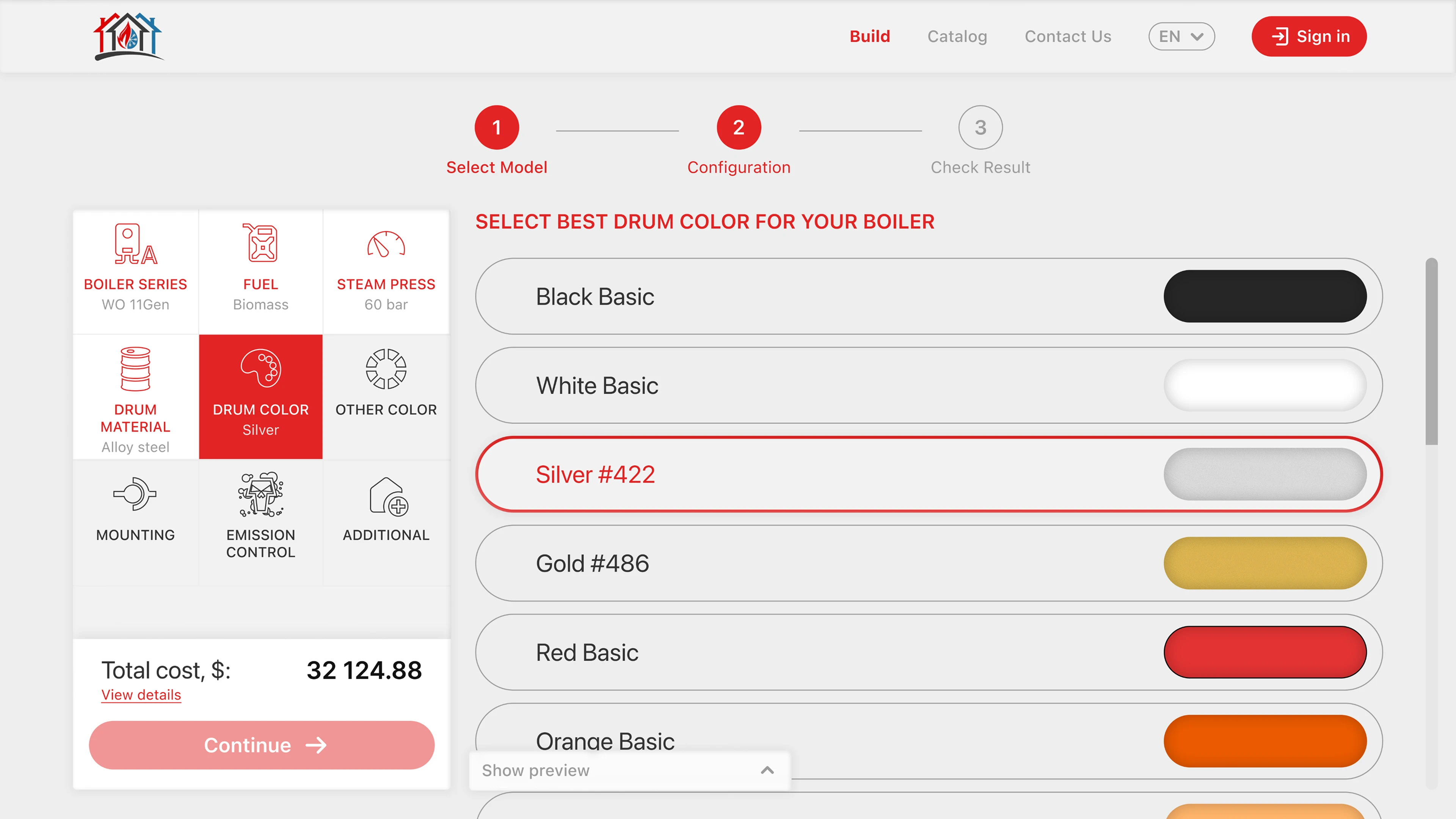

In the mechanism constructor, the user can configure dimensions, materials, drive type, voltage, protection options, markings, holes, dimensions and other critical parameters. Depending on the selected values, the model changes in real time, allowing to avoid errors at the early stage of design.

2. Checking compatibility and technical limitations

Mathematical dependencies between parameters are supported, including limits on permissible ranges. The industrial configurator automatically excludes configurations that are technically impossible or that contradict production standards. For example, it is impossible to select a motor that does not fit the housing or speed. Compatibility conditions can be updated as needed without changing the constructor architecture.

An AI agent can be integrated into the configurator, which will select materials and components, check compliance with regulations, predict the behavior of systems under different operating scenarios, and learn from data from past projects. In this connection with an intelligent assistant, the industrial constructor will become a full-fledged expert, capable of making technically sound decisions.

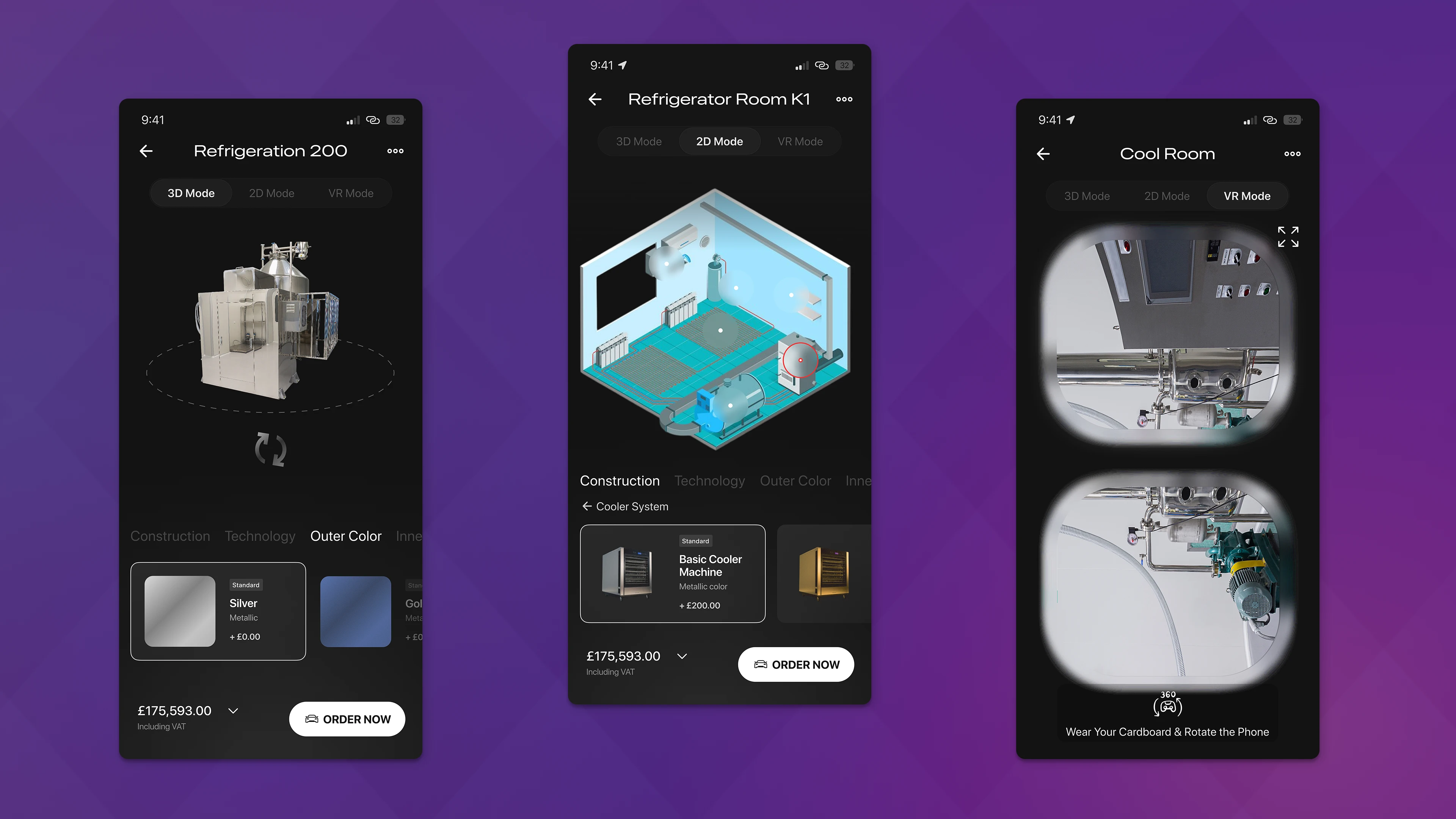

3. Interactive 2D/3D equipment modeling

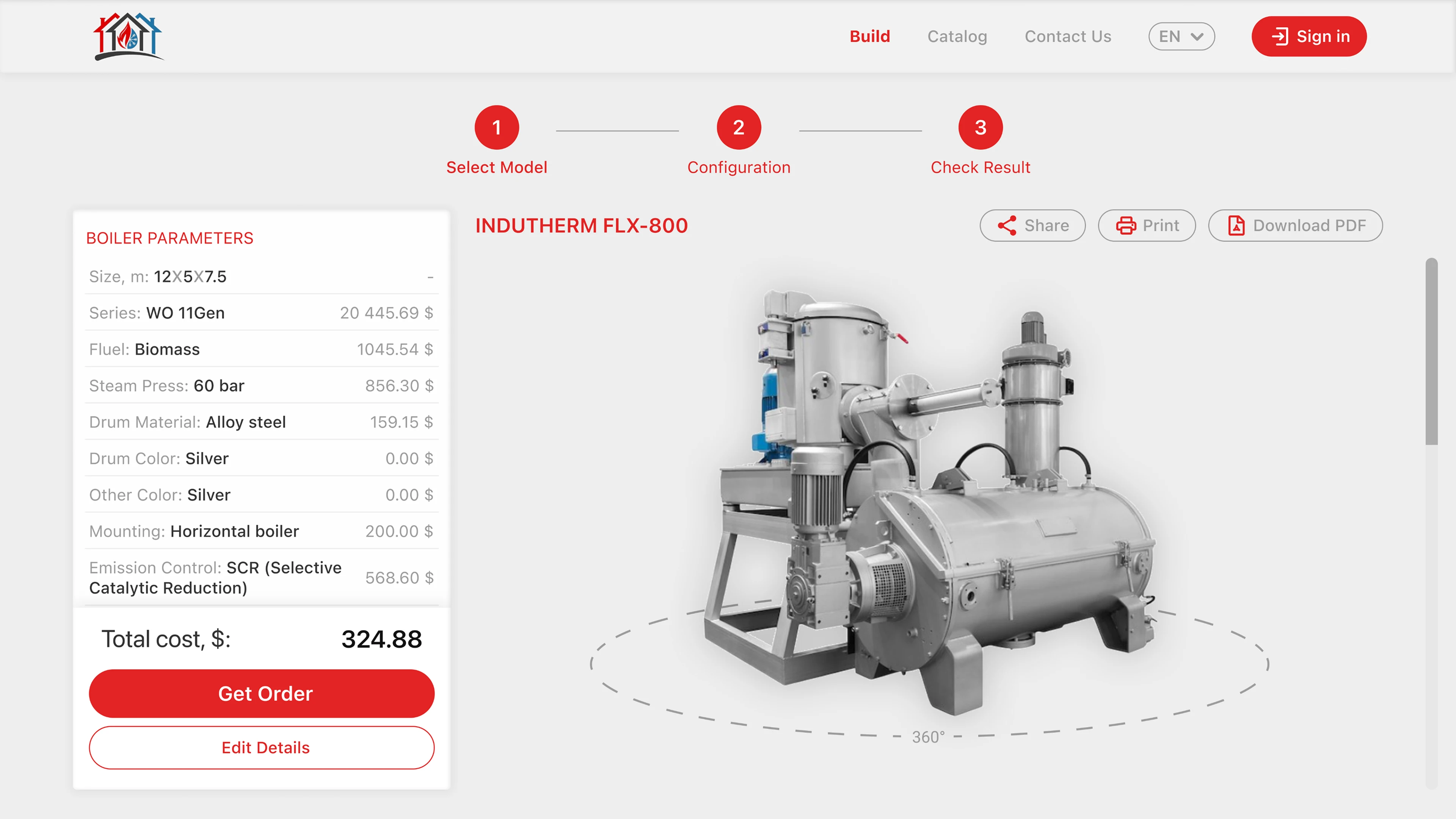

In the online constructor for industrial enterprises, the user receives a visual representation of the future product in the form of a three-dimensional model or technical drawing with the ability to rotate, scale, display internal elements and sections, and animation of the operation of nodes. It is possible to switch from 3D format to drawings or select 2D planes with dimensions.

4. Automatic cost calculation

The online configurator for manufacturing enterprises instantly generates a cost based on various factors: configuration complexity, volume, material, production time, currency exchange rate, and additional options. It is possible to set individual discounts, dealer prices, seasonal coefficients, and even compare multiple configurations by price.

5. Formation of technical documentation

Automatic document generation significantly saves time and reduces the likelihood of errors when transferring information between departments. The industrial online constructor can generate a bill of materials (BOM), drawings in various formats, a technical specification for production, a product passport, user manual, and a commercial offer in PDF or Excel.

6. Integration with internal systems

The configurator integrates with ERP, CAD/PDM systems, component databases, and online calculators. This connection allows you to automate all stages – from product selection and visualization to the formation of technical specifications, specifications, and data transfer to the production department.

At your request, the constructor can become part of an individual CRM system for production, which records all requests, forms customer cards, stores history and automatically creates leads based on the collected models. We develop such turnkey solutions.

Which industries require 2D/3D modeling of equipment, parts and mechanisms?

Our team can develop a constructor for industrial facilities in various areas of production, including as part of project activities.

For the design of production equipment

This tool is used for designing production lines, automated complexes, and non-standard machines. It allows you to visually assemble a configuration taking into account dimensions, drive type, power, operating modes, and interaction between nodes.

For the design of ventilation and air conditioning equipment

Designing ventilation units, air conditioning and recovery systems requires accurate calculations of air flow, pressure, route length, noise characteristics and types of filtration. In the online constructor, you can model exhaust and supply ventilation systems taking into account the area, heat release, number of work zones, and pollution sources. The tool allows you to select equipment (fans, filters, ducts), calculate aerodynamics and noise indicators, and generate route drawings and installation specifications.

For engineering equipment design

Online configurator for industrial enterprises automates the design of engineering equipment systems: water supply, heating, sewage, power supply and other communications. For example, the online pipe constructor can take into account regulatory requirements, technical characteristics of buildings, operating modes. Provides the opportunity to collect coordinated schemes and calculate the parameters of the systems.

For oil and gas equipment design

Industrial configurator for oil production and processing enterprises allows you to model pumping stations, separators, heat exchangers, tanks and other equipment for the production, storage and transportation of oil and gas. Supports material selection, pressure calculation, component compatibility control and generation of operational documentation.

For the design of technological equipment

Used for assembling lines and installations in the chemical, food, pharmaceutical and other industries. Provides accurate selection of technological components: pipelines, pumps, heat exchangers, sensors. Implements visual modeling of product flow and performance parameters.

For the design of electrical panel equipment

2D/3D constructor automates the layout of electrical cabinets: selection of circuit breakers, busbars, protection modules, RCDs, mounting elements. The program for modeling electrical circuits checks the compatibility of components, calculates the load and ensures compliance with regulations.

For the design of lifting equipment

Required for designing mechanical equipment for elevators, cranes, hoists, trolleys, winches. Supports calculation of load capacity, working radius, drive type, ropes and blocks. The tool can include selection of all mechanical components, including gearboxes, guides, cabins and frames.

For capacitive equipment design

In the online constructor for industrial enterprises, it is possible to design tanks, vats, silos, selecting the volume, shape, wall thickness, materials and type of insulation. The tool calculates pressure, temperature conditions, corrosion resistance and transportation.

For designing non-standard equipment

The program is suitable for solutions that do not have typical templates. It allows you to fully adapt the design to the customer's requirements, assemble a model in a free form, with automatic verification of manufacturability and the ability to issue documentation for custom production.

For metallurgical equipment design

The online steel structure configurator is necessary for designing rolling mills, blast furnaces, heat treatment furnaces, and other equipment in the metallurgical cycle. It takes into account extreme temperatures, mechanical loads, energy efficiency, and integration into existing infrastructure.

For boiler equipment design

Custom constructor for industrial and domestic boilers, with a choice of burners, heat exchangers, thermal insulation and automation. It has the ability to calculate power, efficiency, fuel, emissions and operational safety.

For gas equipment design

Allows you to model distribution and reduction stations, gas meters, filters and pipelines taking into account pressure standards, flow rates, leak protection, automation and monitoring.

For the design of refrigeration equipment

This online industrial configurator helps to model cold rooms, chillers, compressor-condensing units. It allows you to calculate heat inflows, select a refrigerant, choose a cooling system and automation components.

For medical equipment design

Allows you to customize operating tables, diagnostic devices, sterilization units, and other medical equipment. Takes into account ergonomics, hygiene standards, room sizes, and utility connections.

For the design of elevator equipment

The industrial online constructor supports the design of elevators, conveyors, grain dryers, silos and other equipment. Covers parameters such as productivity, crop type, lifting height, unloading method and storage conditions. Can generate transportation schemes and equipment specifications.

Benefits of implementing an online constructor at an industrial enterprise

A custom configurator for industrial enterprises is a technology that will make your business more flexible, accurate, and competitive, as it shows its effectiveness immediately after implementation.

- Shortens the sales cycle , as the client makes a decision faster, receiving not just a commercial offer, but a full-fledged project, supported by a 3D model and accurate calculations.

- Reduces the burden on managers, engineers, and the technical support department by automating parameter checking, component selection, calculation, and documentation generation.

- Flexible adaptation to the specifics of a particular production – we create logic and web interfaces that take into account the specifics of assembly, technological processes and sales channels. For example, an online constructor of a chimney or an individual greenhouse.

- Increases order accuracy and reduces the risk of errors related to the human factor: missed items, incompatible parameters, inaccurate calculations.

- Allows you to create unique products - quickly and efficiently, without the expense of manually designing each new modification.

- Increases customer engagement by making choices clearer and more confident, thanks to an interactive interface.

- Easily scalable – when expanding the range or introducing new models, it is enough to update the logic or component base, without global changes to the system.

- Works on any device and easily integrates into existing digital ecosystems. We develop online configurators in the format of PWA applications, ensuring cross-platform compatibility, fast loading and integration with other systems.

- Strengthens the company's image as a technological and customer-oriented business, creating advantages over competitors and improving the reputation of a reliable partner.

Cost of developing a constructor for industry

Developing a configurator for industrial products and equipment requires a comprehensive approach, as the projects include complex technical parameters, various materials, complex modules for calculating compatibility, and additional integration with ERP or CAD systems. Because of this, the cost and implementation time vary significantly depending on the level of the project and the format of the constructor.

Below are approximate estimates of the cost and implementation time for 2D and 3D industrial configurators. The final price and time are formed after a detailed study of the technical specifications, the complexity of the structures, and the specifics of business processes.

| Constructor Format | Level | Key Functions | Estimated Cost | Terms |

|---|---|---|---|---|

| 2D constructor | MVP | Basic parameter selection interface (dimensions, materials, component types), basic compatibility and cost calculations, minimal visual feedback | $6 000 – $9 000 | 6–8 weeks |

| 2D constructor | Standard | Advanced configuration selection, more accurate component compatibility calculations, integration with basic ERP/CRM, basic configuration reports | $9 000 – $14 000 | 8–10 weeks |

| 3D constructor | MVP | 3D product visualization, minimum parameters for configuration, basic animation of moving parts, calculation of cost, materials and compatibility | $14 000 – $25 000 | 3–4 months |

| 3D constructor | Standard | Detailed 3D visualization, advanced configuration parameters, integration with CAD/ERP systems, generation of specifications and reports, basic motion simulation | $25 000 – $45 000 | 5–7 months |

| 3D constructor | Advanced | Full 3D animation and photorealistic visualization, complex interactions between components, integration with all internal systems, advanced design optimization algorithms, connection of VR/AR module for presentations and testing | $45 000 – $75 000+ | 7–10 months |

What is included in the MVP, Standard and Advanced levels

The configurator level determines the depth of functionality, the complexity of integrations and the user's capabilities in working with industrial products. Below is a brief description of each level, which helps to navigate in choosing the best option for your business.

- MVP is a minimum viable product that provides basic customization of a product or equipment and demonstrates key functions. Usually includes only the necessary parameters and simple visualization.

- Standard is a mid-level constructor that covers most typical usage scenarios. It has advanced parameters, integration with ERP/CAD, report generation and more complex compatibility calculations.

- Advanced is a full-fledged tool for complex products, including photorealistic 3D animation, integration with all internal systems, advanced optimization algorithms and additional functions for VR/AR. Designed for complex projects and maximum automation of the configuration process.

Stages of developing a constructor for industrial production

Each project we implement goes through several mandatory stages. This approach allows us to create the best solutions for companies of all sizes and industries.

1. Requirements analysis

The design of production equipment and parts begins with a study of the business processes of the industrial enterprise, product specifics, and expectations from the implementation of the configurator. At this stage, a team of analysts, together with the customer, formulates key goals, functional priorities, and technical constraints so that the industrial online constructor meets real production tasks.

2. Formation of technical specifications

Based on the collected information, our specialists create a detailed technical specification, which describes all the functions, the logic of the configurator, the requirements for integrations and the expected architecture. The TOR defines the scope and framework of the project, ensuring mutual understanding between the customer and the dedicated team.

3. UX/UI Design

Designers develop the interface of the industrial constructor with an emphasis on usability, visual clarity and interaction logic. Particular attention is paid to adaptability for work on different devices, simple and fast modeling of complex products, as well as intuitive parameter management. At this stage, a prototype of the interface is created for coordination with the customer before the implementation of the software code.

Our team uses modern technologies to create an attractive, informative and productive interface. This includes adaptive visualization of components, animation, dynamic rendering of complex scenes and interactive elements. This approach makes the configurator more visual and increases its efficiency in working with large projects.

4. Creating 2D/3D models

For interactive visualization, 2D scenes or full 3D models with different options for materials, textures, colors and variable parameters are developed. Realistic display of objects in the browser is possible thanks to deep expertise in Web 3D, the use of WebGL and other modern tools that provide high performance and cross-platform compatibility.

5. Frontend and backend development

Programmers implement the client part of the constructor using modern frameworks – React or Vue, as well as server logic (Node.js, Python, PHP, etc.). At the stage of implementing the software code, our developers create mechanisms for generating documents, calculating costs, saving configurations and processing user data. If necessary, the configurator is connected to other enterprise platforms.

6. Testing and launch

Comprehensive testing of all functions of the industrial online configurator is carried out, including calculations, model display, correctness of orders and interaction with internal systems. After successful testing, the program is launched into the working environment and employees are trained.

7. Support and Scaling

After developing and implementing an online constructor for an industrial enterprise, we provide technical support: we update functionality, add new products, models, and configure integration with new systems. Our products are easily scalable and adaptable to business expansion.

How to order an online industrial constructor

To order the development of an online configurator for a manufacturing enterprise, contact AVADA MEDIA with an idea or technical request. We form a dedicated team of specialists, including business analysts, UX/UI designers, frontend/backend developers, and QA testers, who accompany the project from idea to full implementation, and if necessary, continue to maintain the program.

Our team is ready to develop a constructor for industrial equipment, mechanisms and products. We offer transparent terms of cooperation, reasonable cost and support after launch.

FAQ

-

Is it possible to restrict access to certain settings for different users?

In the individual configurator, you can flexibly configure rights: for example, the manager only assembles the product and transfers it for calculation, and the engineer adjusts the technical parameters.

-

Can I use one constructor for multiple product lines?

The program architecture allows you to create separate scenarios and assembly rules for each line with the ability to switch.

-

Does the constructor support working with products manufactured according to DSTU or other standards?

The configurator for manufacturing enterprises can take into account all regulatory requirements and automatically block combinations that do not meet technical or industry standards. This is important for certified products.

-

What can you do in the online commercial equipment constructor?

It assembles racks, display cases, and shelving from available modules, forms the cost and specifications for the shop. This reduces the number of iterations between the configurator, production, and customer.

-

Can the online polypropylene pipe constructor be adapted to non-standard pipeline layouts?

Yes, we develop configurators with flexible logic that takes into account non-standard geometry, limited spaces, connections to existing networks, etc.

-

Can I use an online plumbing constructor to estimate costs and generate estimates?

This is one of the most popular features: the configurator can automatically calculate the length of pipes, the number of fittings and other components, generating an estimate and even exporting it to PDF. For companies that design and install engineering systems, we can additionally develop a CRM, as was implemented for the engineering company SPETSPOZHSERVIS. You can find out the details of the case in our Portfolio. The integration of the constructor and CRM forms a single ecosystem for managing orders, customers and technical documentation.

-

How is the logic of moving elements implemented in the online mechanism configurator?

Using interactive 3D scenes and animation, you can demonstrate the operation of the mechanism in real time, including rotation, sliding, and interaction of parts.

-

Can an online mechanism constructor be used as part of a training process for technical specialists?

The configurator can be adapted for educational purposes - add hints, a step-by-step assembly mode, and built-in construction correctness checks. It implements the modeling of moving joints, collision checking, calculation of permissible loads, and export to CAD systems or STL format for 3D printing.

-

Is there a cost difference between 2D and 3D constructors?

Yes, 3D visualization requires more resources: modeling, scene optimization, rendering, as well as a more complex front-end. This directly affects the final price of the configurator.

-

How long does it take to develop a constructor for industry?

The project can take from 4 months depending on the functionality, type of visualization, number of users, and source data.