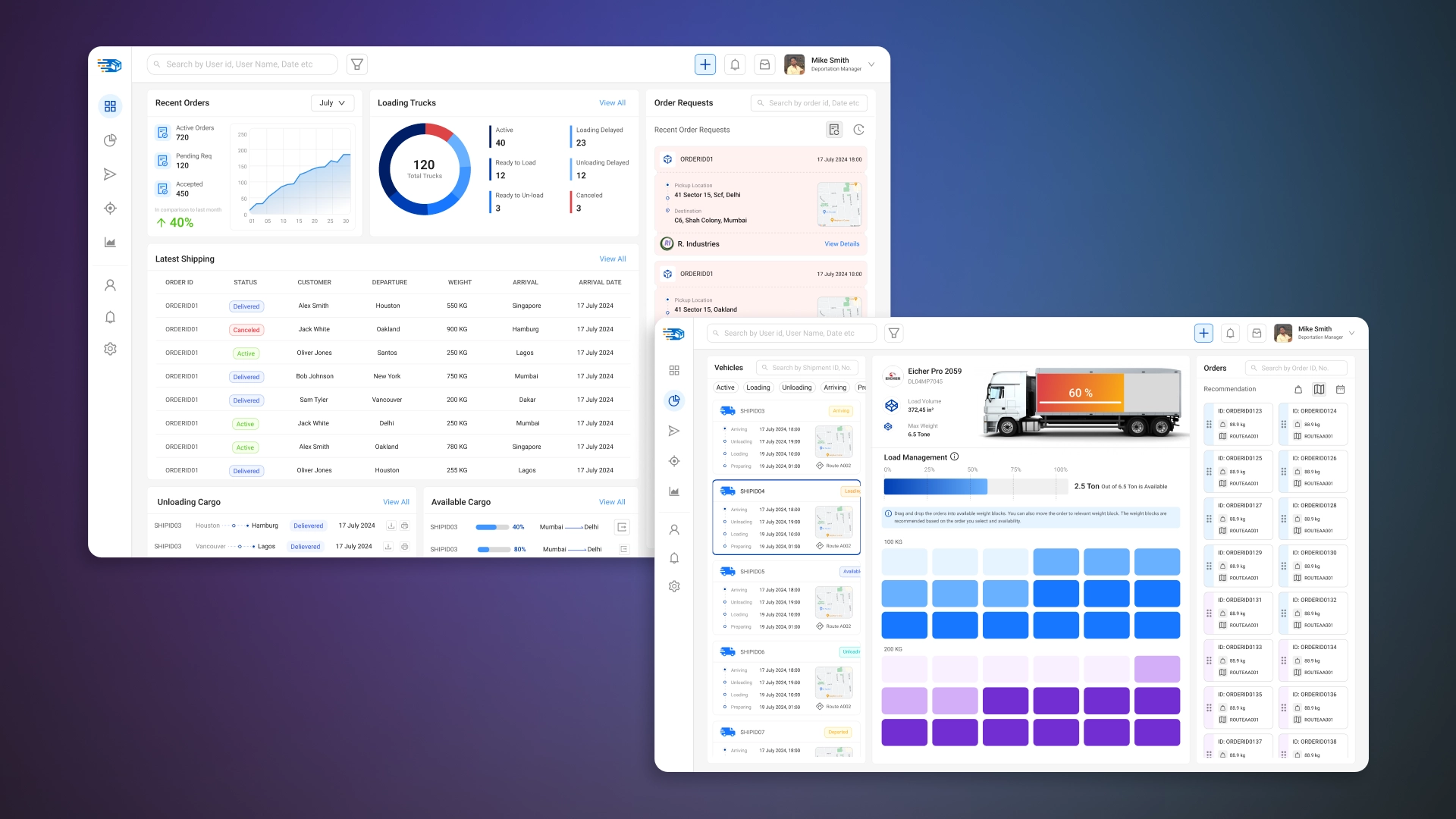

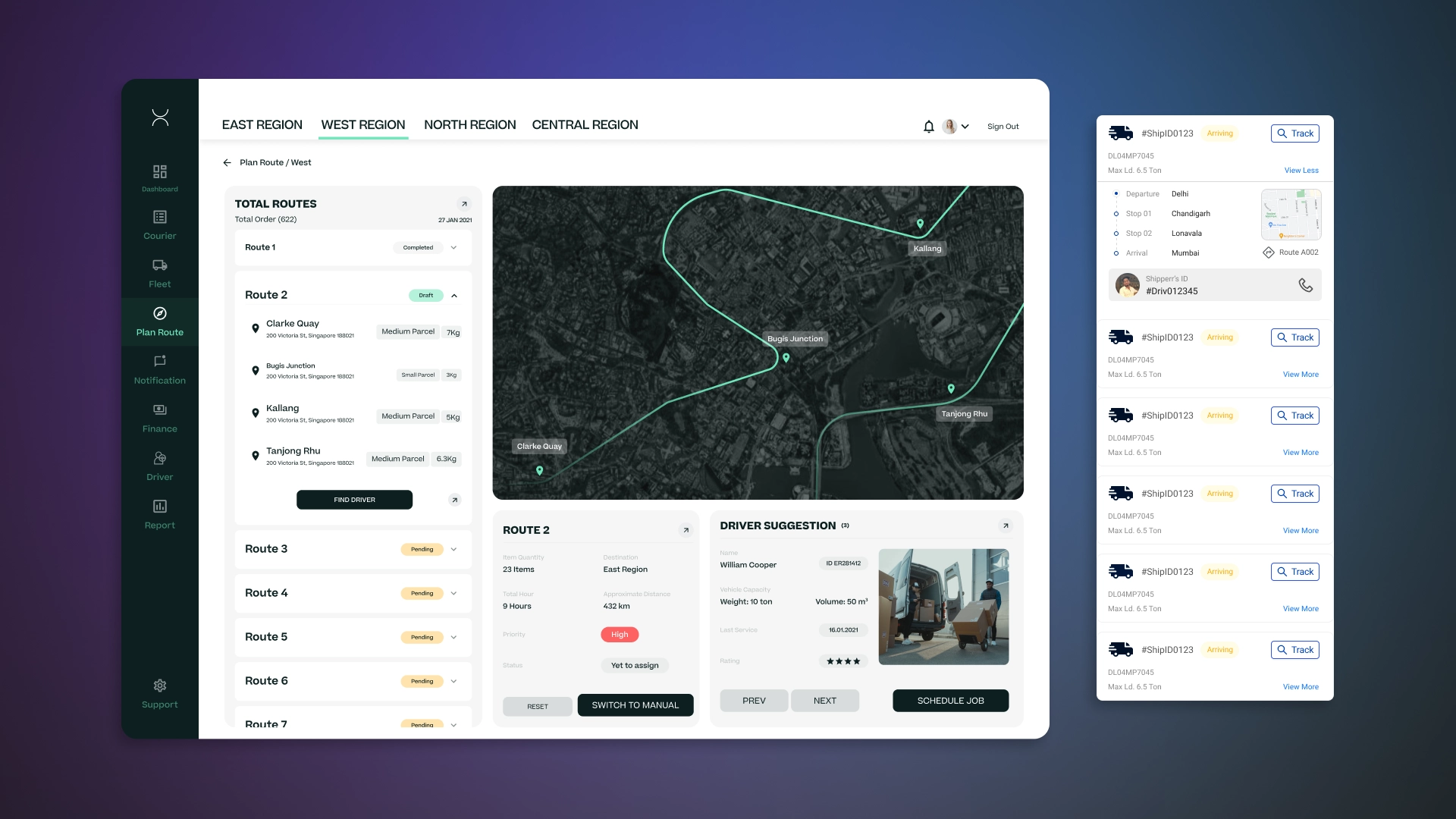

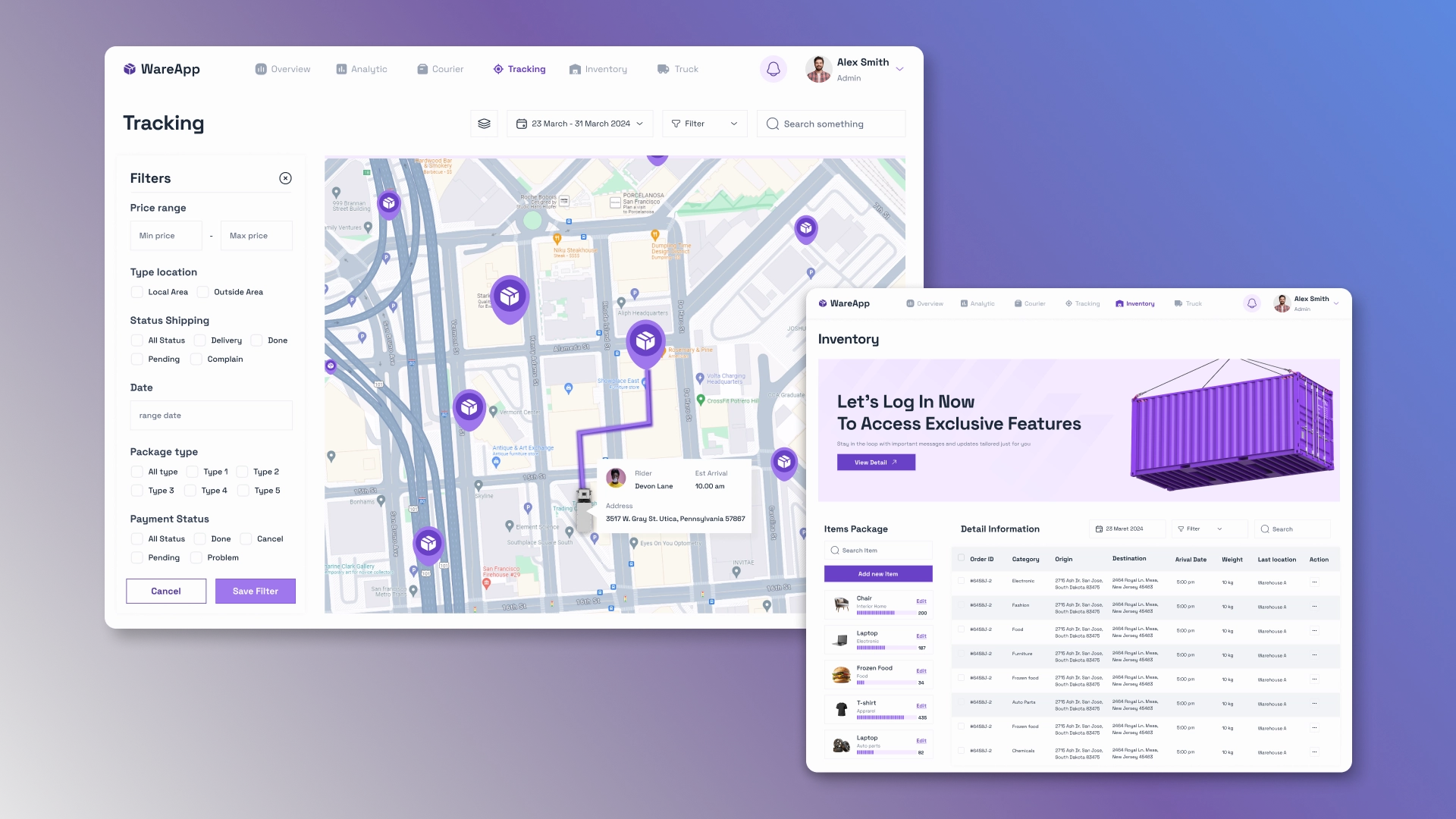

Development of software for logistics automation

Logistics is one of the most complex industries in business, requiring high precision, coordination, and lengthy calculations. And when the COVID-19 pandemic led to a sharp increase in online shopping, it became an unprecedented stress test for the global supply chain. The increased workload increased the need for logistics companies to automate processes that help optimize and speed up the transportation of goods at all stages - from production to delivery to the end consumer.

What are the benefits of transport logistics automation?

In the modern logistics industry, where millions of transactions are processed daily, accuracy and speed play a key role in the success of the entire business. Accounting for cargo, routes, delivery times - all this requires not only attention, but also a huge investment of time and effort. And the larger your company, the greater the risk of errors, since the human factor inevitably makes its own adjustments. But automation opens up completely new opportunities for companies.

Modern technologies such as artificial intelligence (AI), blockchain, IoT and virtual reality integrate and complement each other perfectly, ensuring the continuous processing of complex transactions. In addition, they eliminate most of the problems associated with cargo transportation, digital security and documentation.

Let's look at the main advantages that logistics software provides:

- Optimizing order fulfillment costs . Automated systems reduce costs by optimizing routes, choosing the most profitable delivery methods, and automatically distributing tasks among employees. This helps avoid unnecessary expenses on fuel, time, and labor.

- Effective inventory management . Modern logistics software uses various IoT devices and computer vision to accurately track inventory in real time. With their help, the company receives reliable data on the quantity of products in the warehouse, its location and condition. This reduces the risk of shortages or overproduction, simplifies warehouse management and contributes to more effective procurement planning.

- Reduced delivery times . Automation systems help process orders faster and organize their delivery. Thanks to optimized routes and efficient transport management, orders are delivered to customers in a shorter time, which increases the company's competitiveness in the market.

- Increase in delivery volumes . Machines are capable of processing much more data than humans, and they do it much faster and more accurately, providing for all the steps to solve the tasks at hand. This allows the company to significantly increase the volume of transportation, and accordingly, increase its profits.

- Reduced risk of errors . The software minimizes the human factor, thereby reducing the likelihood of errors in order processing and inventory management. This increases the overall accuracy of operations, as well as reduces the risk of financial and reputational losses.

- Improved analytics and forecasting . Collecting and analyzing data on logistics operations in an automated system makes it possible to accurately forecast demand, conduct long-term calculations, and make informed business decisions. Together, this allows the company to operate more efficiently and contributes to its successful development.

Types of software for transport logistics

Transport logistics requires the use of various software solutions that help companies effectively manage both their internal operations and interactions with partners. Let's look at the main types of software that are most often used in this industry:

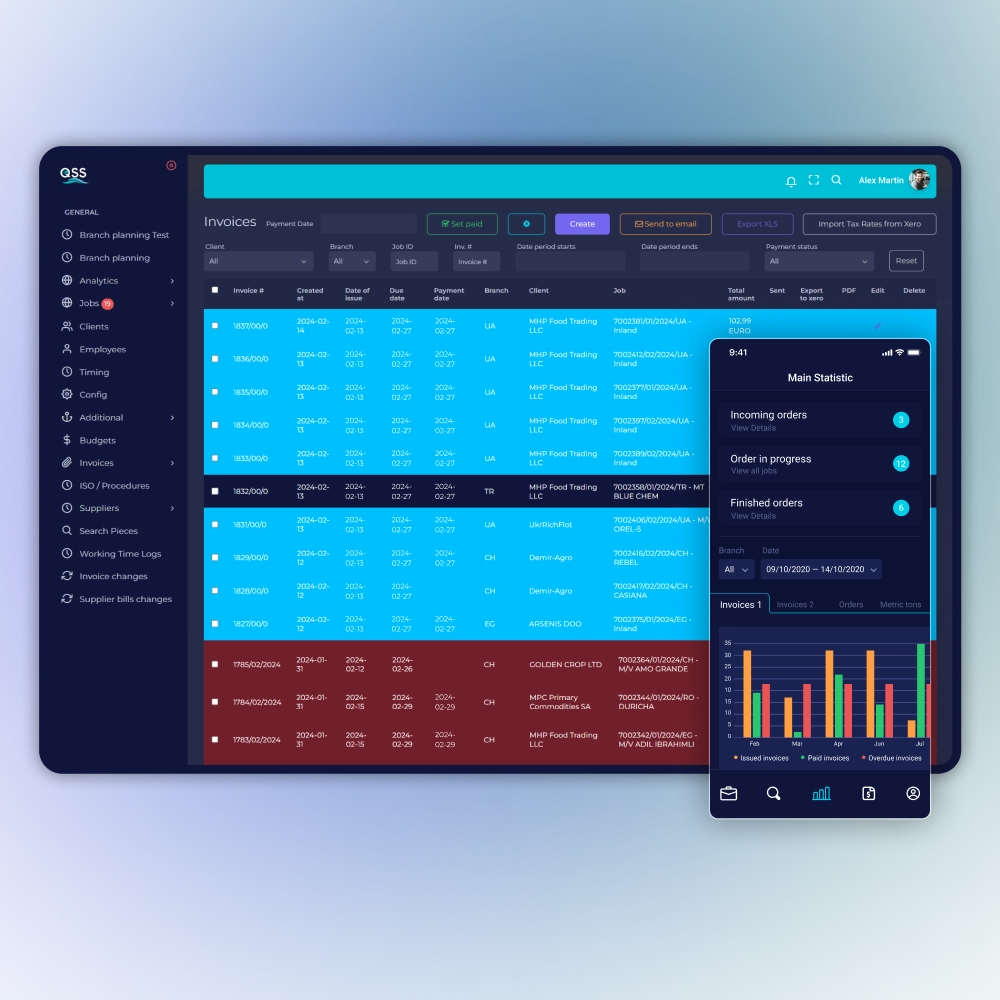

- Transport Management Systems (TMS) . Such programs cover all tasks related to cargo transportation. In particular, they help to choose optimal routes, manage the vehicle fleet, track deliveries and maintain documentation, which reduces costs and increases business efficiency.

- Supply chain management (SCM) software . Combines all stages of the supply chain into a single system, thereby improving coordination and increasing the efficiency of logistics.

- Fleet Management Systems (FMS) . Designed to control and manage company vehicles. In particular, FMS monitors the condition of vehicles, plans their maintenance, analyzes the efficiency of fleet use and optimizes transport routes.

- Route mapping systems . Used to optimize logistics routes. They help determine the fastest and most cost-effective routes, taking into account road conditions, travel time, and other factors.

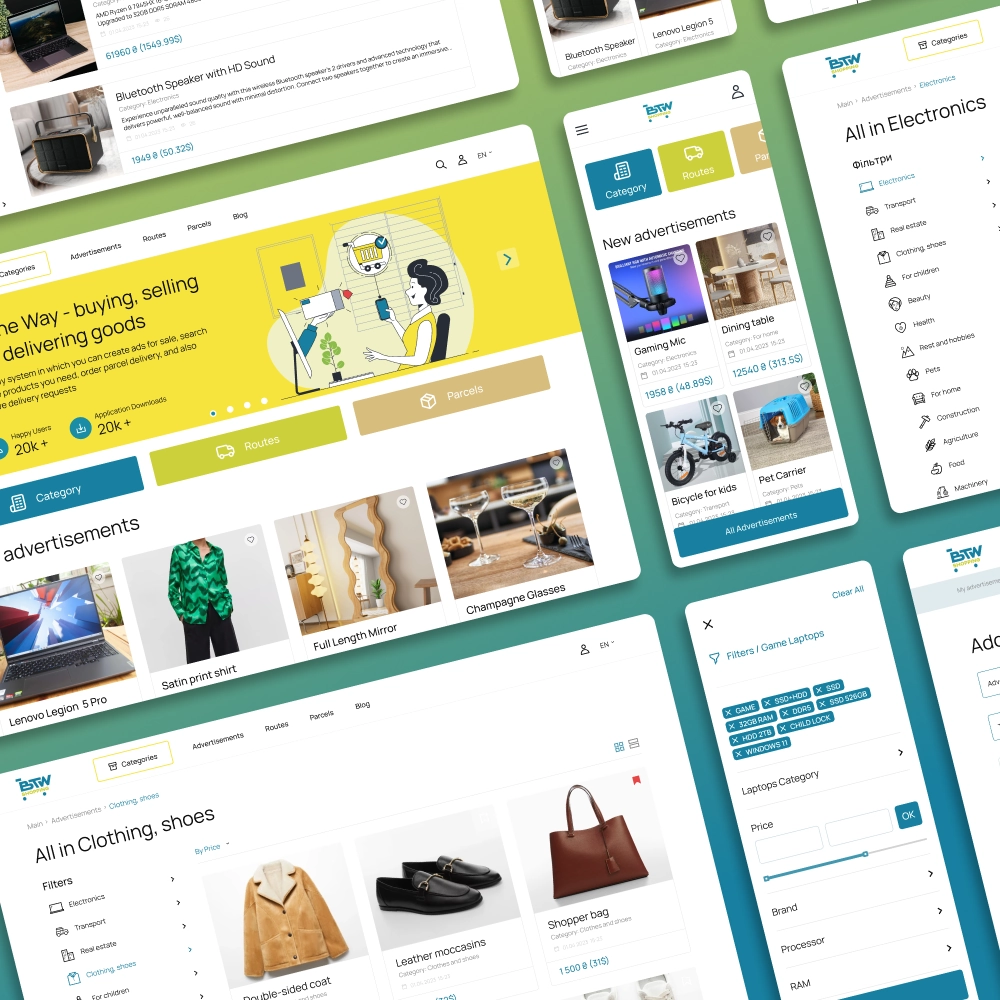

- Asset tracking systems . These systems allow tracking the location and condition of transported goods, thereby increasing transparency and control at all stages of the logistics chain.

Why Invest in Custom Transport Management Software Development

Even today, many logistics companies rely on human resources to operate, and their digitalization is, in most cases, limited to the use of spreadsheets or standardized “out-of-the-box” solutions.

However, the market dictates its own terms. Modern users have long been accustomed to convenience and want purchases to be in their hands in a matter of hours, which is why they demand ever higher speed and accuracy of operations from businesses. And achieving this without customized software that takes into account the unique processes in your company is almost impossible.

At AVADA MEDIA, we understand the challenges and difficulties that logistics businesses face on a daily basis, and we offer the development of innovative digital solutions that help overcome them successfully. Let's look at the main reasons why it's worth investing in creating custom software.

Economic rationality

The availability of "boxed" software is more of a stereotype than a truth. Integrating a ready-made program into the processes of a large logistics company can take several months and require serious investments. At the same time, the effectiveness of such a product is questionable, since it solves business problems only superficially. Therefore, it is more expedient to redirect the budget and time to the implementation of individual software, which is initially created taking into account the unique needs of your company.

Relevance of technologies

Most standard supply chain IT solutions have been on the market for decades. Such programs are characterized by technical limitations, which pose a significant obstacle to their integration into modern businesses.

By choosing custom development, you take a step towards innovative technologies that are more efficient, easily expandable and meet the current needs of the company. For example, by developing your own software, you can delegate data processing and route building to AI, and transfer cargo status monitoring to IoT devices. This will ensure maximum accuracy and speed of your business.

Compliance with requirements

Logistics is a complex and diverse market, where each company has its own specifics, niche and unique internal processes. Therefore, there is no “universal” software for this industry that would be equally effective for everyone.

Custom development, on the contrary, allows you to take into account the specifics of your business: the nature of operations, the logic of interaction with clients and partners, as well as the necessary integrations. Plus, such software will continuously expand, in parallel with the growth of your company, due to which it will not lose its relevance over time.

Safety

Custom software is the best solution in terms of cybersecurity. It gives the company full control over its data and eliminates the possibility of confidential information leakage from third-party platforms and services.

How to order software development for logistics in AVADA MEDIA?

Starting cooperation with an IT company always causes a certain amount of excitement. Every entrepreneur wants the development team to correctly understand their needs, and the end result to fully meet their expectations. Therefore, to avoid the risk of misunderstanding or double interpretation of tasks, we have organized the most transparent process of interaction with the customer from the very first communication.

This is how the beginning of cooperation in our company is organized:

- You leave a request on the website with a description of your project.

- Our specialists carefully study the request and contact you to clarify the details of the project, answer questions and offer the best technical solution.

- Once the project goals are defined, we carry out an accurate calculation of the deadlines and budget, determine the software quality criteria, and then record them in the contract.

- We form a team of developers and begin implementing the software, strictly following your requirements and established deadlines.

Why you should choose AVADA MEDIA for creating logistics software

Automation of logistics processes is not just a trend, but a necessity for modern companies. Investments in the development of individual software will allow you to bring your business to a new level of efficiency, reduce costs and minimize risks associated with the human factor.

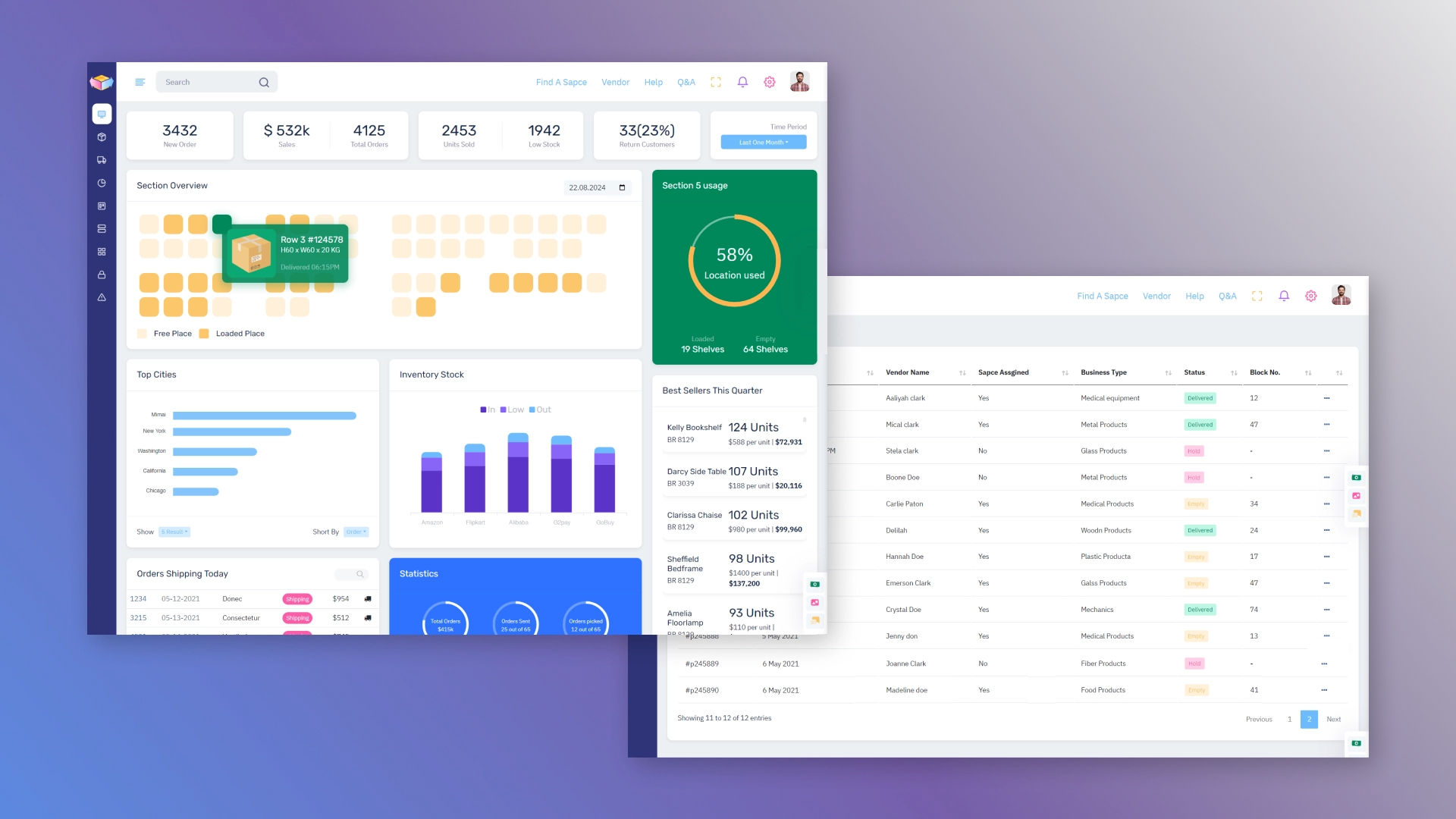

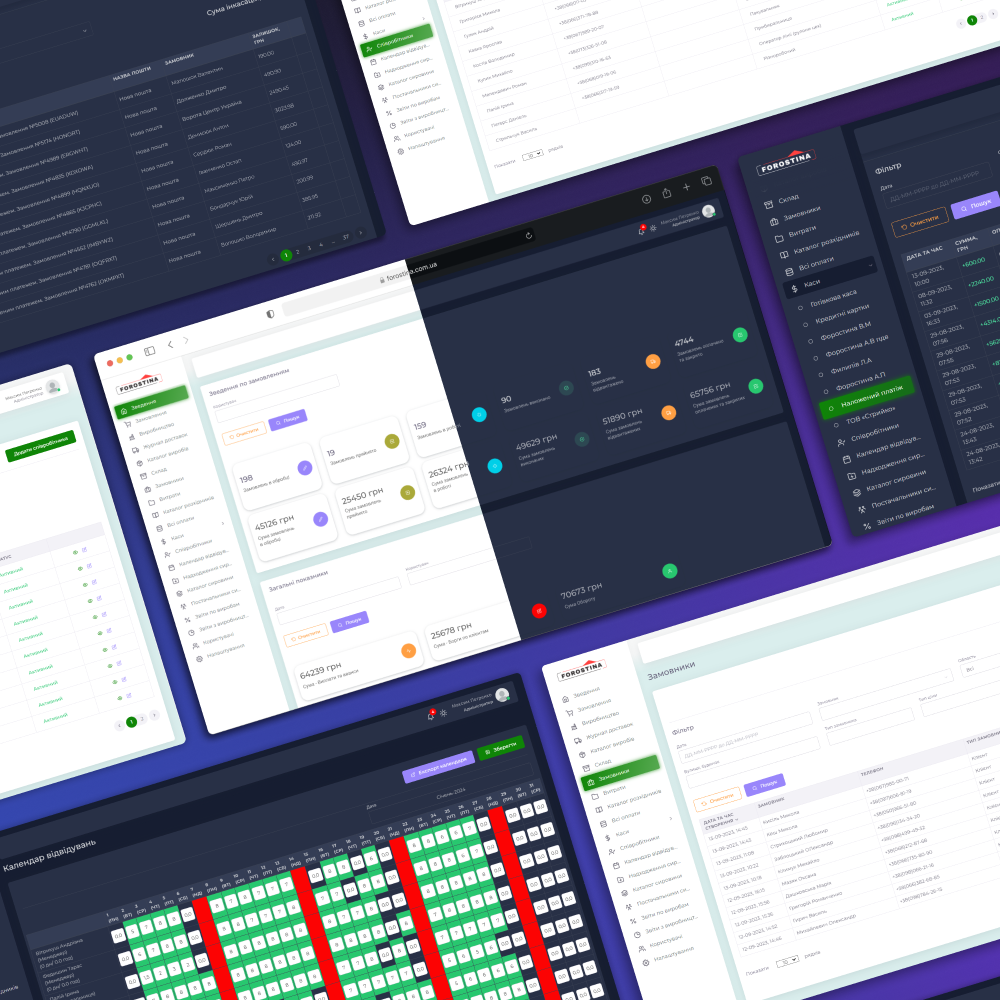

AVADA MEDIA creates innovative software for automating transport and logistics processes both within companies and between business partners. Our developments include fleet and warehouse management systems, route mapping, asset tracking and other digital solutions that increase the efficiency and competitiveness of enterprises in this industry.

By contacting us, you receive not only advanced software, but also the confidence that all processes will work smoothly and efficiently, which will be the key to your company's success in the market.

Questions and Answers

-

Do you follow current trends when developing logistics software?

Today, logistics software development is focused on integration with artificial intelligence and machine learning for route optimization and inventory management. Much attention is paid to cybersecurity and resilience, as well as cloud solutions for increased flexibility and scalability. At AVADA MEDIA, we take into account all current trends to help you implement the most efficient, reliable and functional product.

-

Which companies benefit the most from implementing logistics optimization software?

Custom software is essential for large enterprises with complex and non-standard supply chains. This is especially important for companies in the areas of cargo transportation, e-commerce, manufacturing and retail. Custom solutions help them manage unique logistics tasks more effectively, reduce costs and increase the speed of product delivery.

-

How much does it cost to develop a custom logistics program?

Development usually costs from $10 thousand. However, it is important to understand that everything depends on the required functionality and complexity of the software, so the amount can vary significantly. At AVADA MEDIA, we always recommend starting the project implementation from the design stage, since it allows you to calculate the exact price and find the optimal balance between budget and functionality.