Software development for manufacturing

Innovative digital solutions play a key role in transforming production processes in industrial enterprises. They help automate complex and time-consuming operations, reduce costs, minimize equipment downtime and significantly increase production volumes. The combination of these factors allows companies to successfully grow and develop in competitive markets.

Our experienced experts can help you develop and implement state-of-the-art software for both back office and industrial operations to streamline operational processes at every level and improve the efficiency of your business.

Advantages of IT solutions for manufacturing

In recent years, the industry has been rapidly developing and introducing innovations. But what real benefits does digitalization bring to industrial companies? Let's look at this issue point by point:

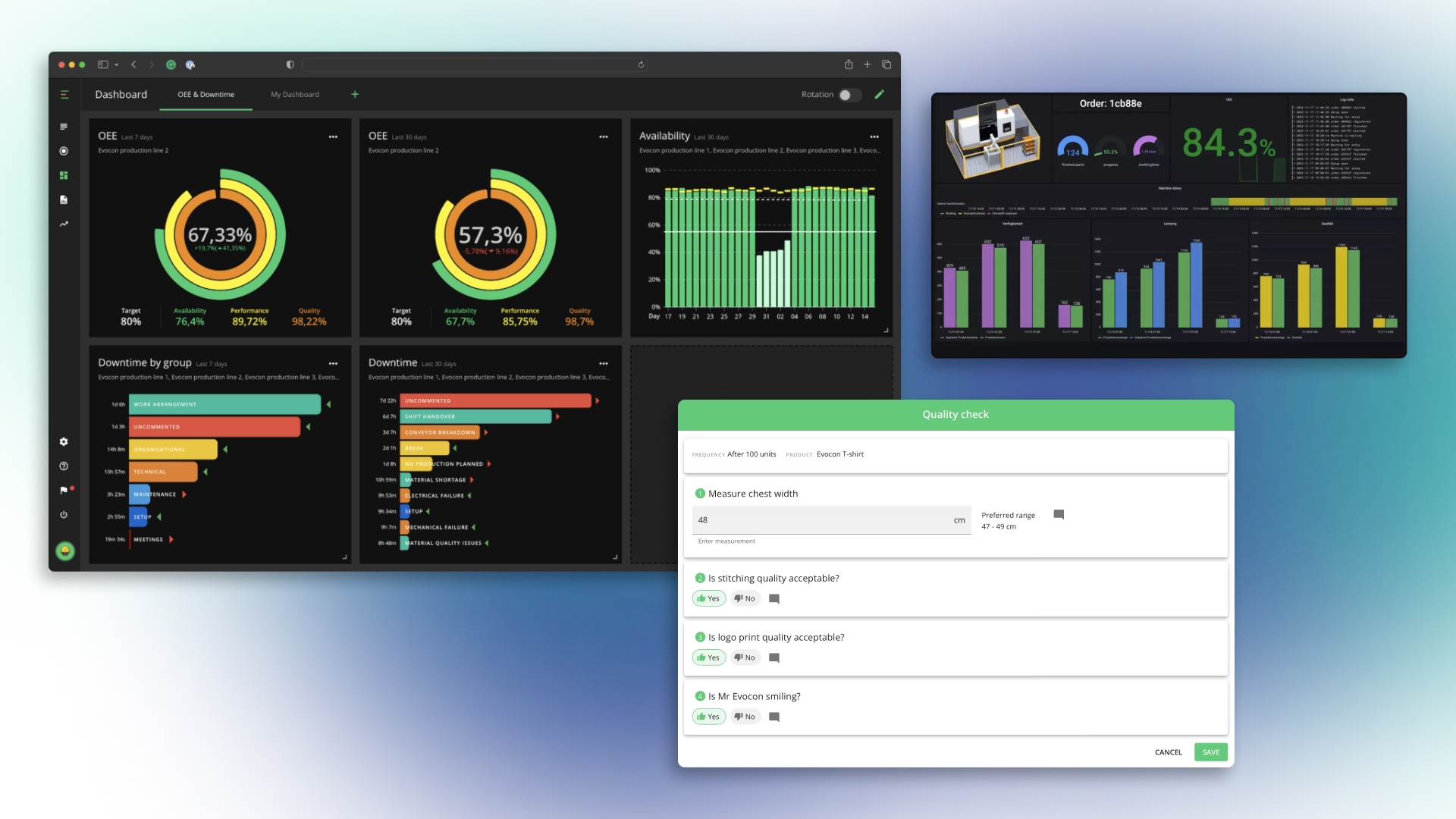

- Optimization of business processes. Modern IT solutions help automate many tasks in a manufacturing enterprise, such as equipment management and maintenance planning, procurement, product quality control and others, which reduces the likelihood of errors and speeds up work completion.

- Cost reduction. Innovative technologies contribute to more efficient use of raw materials and resources, improve logistics and minimize human labor, which reduces operating costs of the enterprise and increases its profitability.

- Increased flexibility and adaptability. Manufacturing software makes it possible to quickly reconfigure production lines to produce new products or change production volumes. This helps companies easily adapt to a rapidly changing market and increases their competitiveness.

- Improving customer interaction. Customer service is an important part of any industrial enterprise. Modern digital systems, such as CRM, help establish effective and personalized interactions with partners and increase their satisfaction.

- Improving product quality. Automated systems provide precise control of production parameters, which significantly reduces the percentage of defects and improves the quality of products.

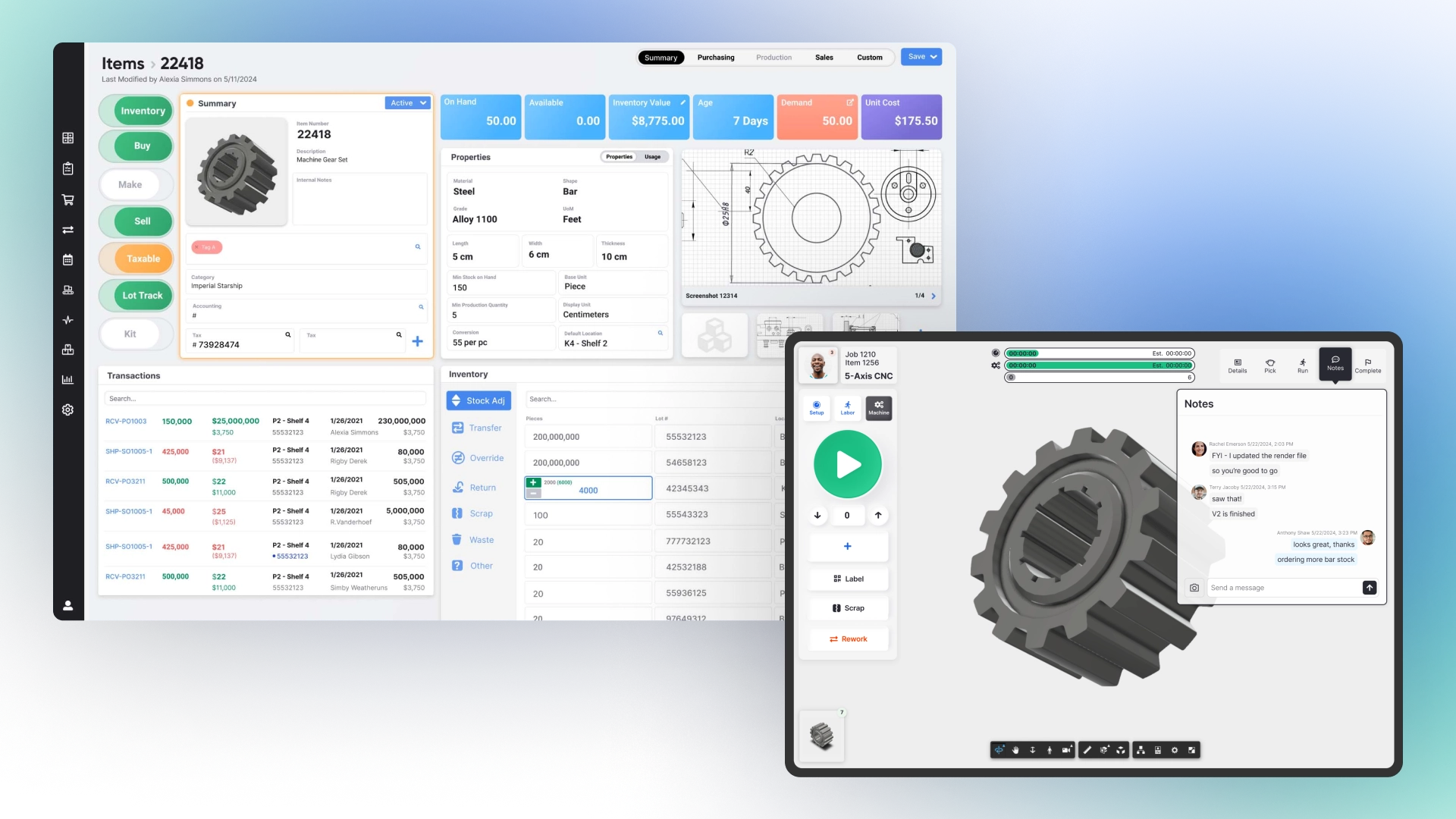

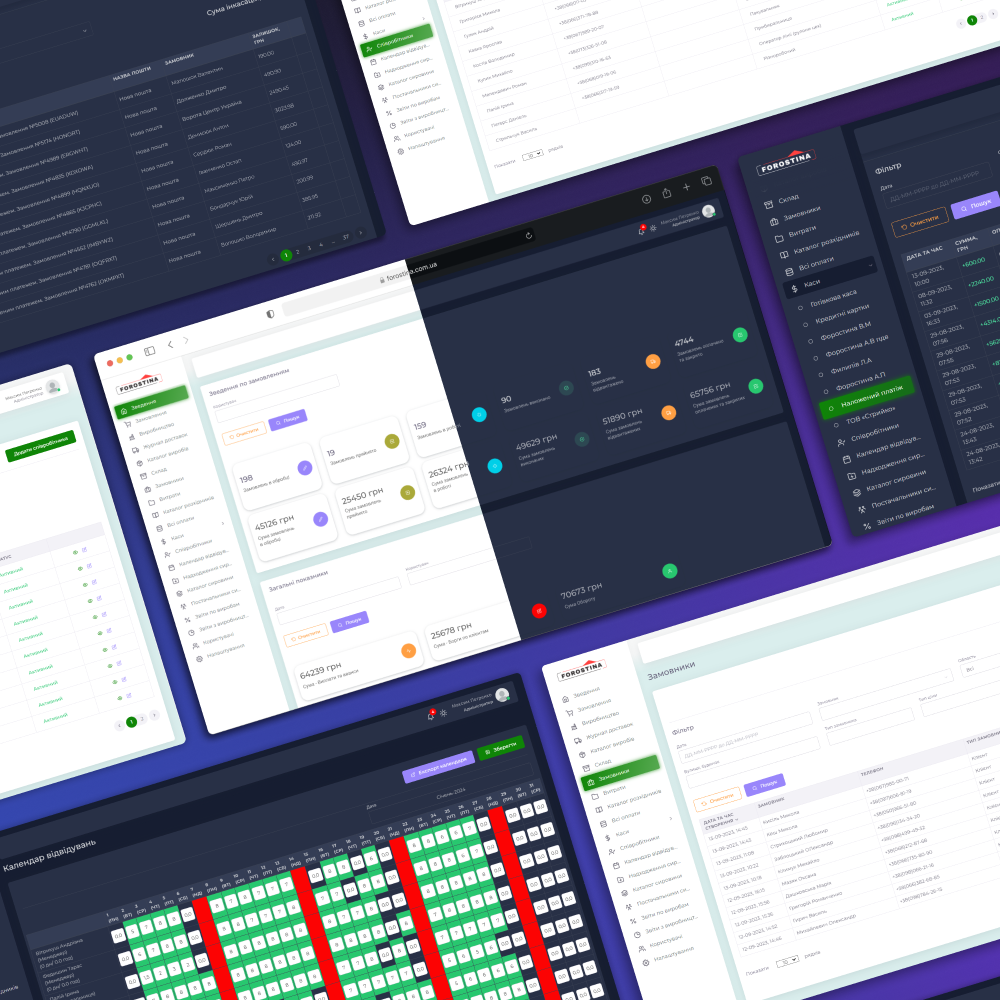

Custom manufacturing solutions from Avada Media

Our team develops and implements custom digital solutions for industrial businesses that help automate production processes and increase the efficiency of the entire enterprise. In particular, our competencies cover the sale of such products.

ERP systems

ERP systems improve resource management and increase the efficiency of industrial enterprises through the integration and automation of business processes. They provide centralized access to up-to-date information, facilitate faster decision-making and increase control over financial flows.

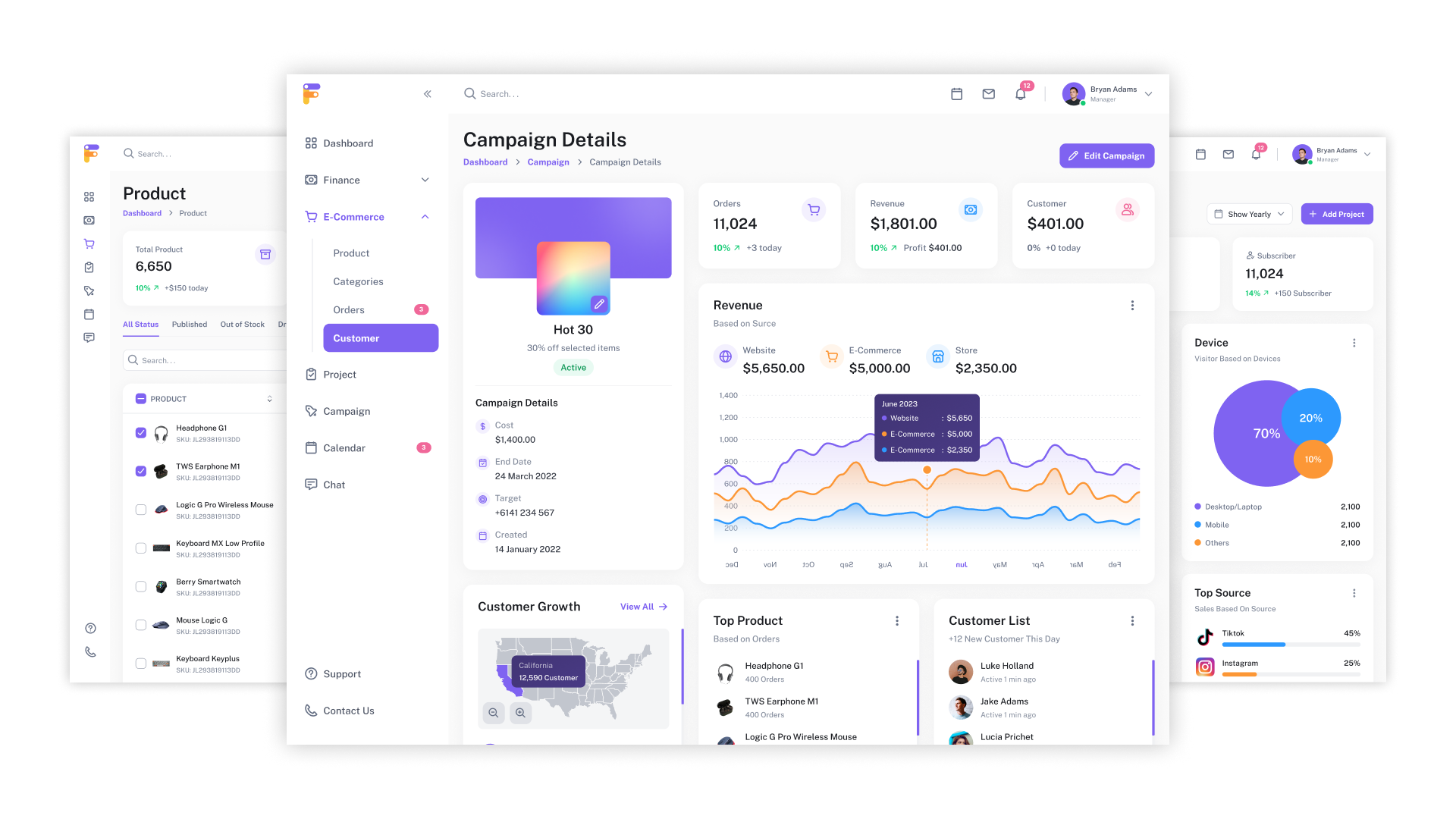

B2B portals

Help industrial enterprises improve interactions with suppliers and customers by automating purchasing and sales processes, which reduces costs and increases efficiency. They provide access to more business partners and new markets, helping to expand business and increase profits.

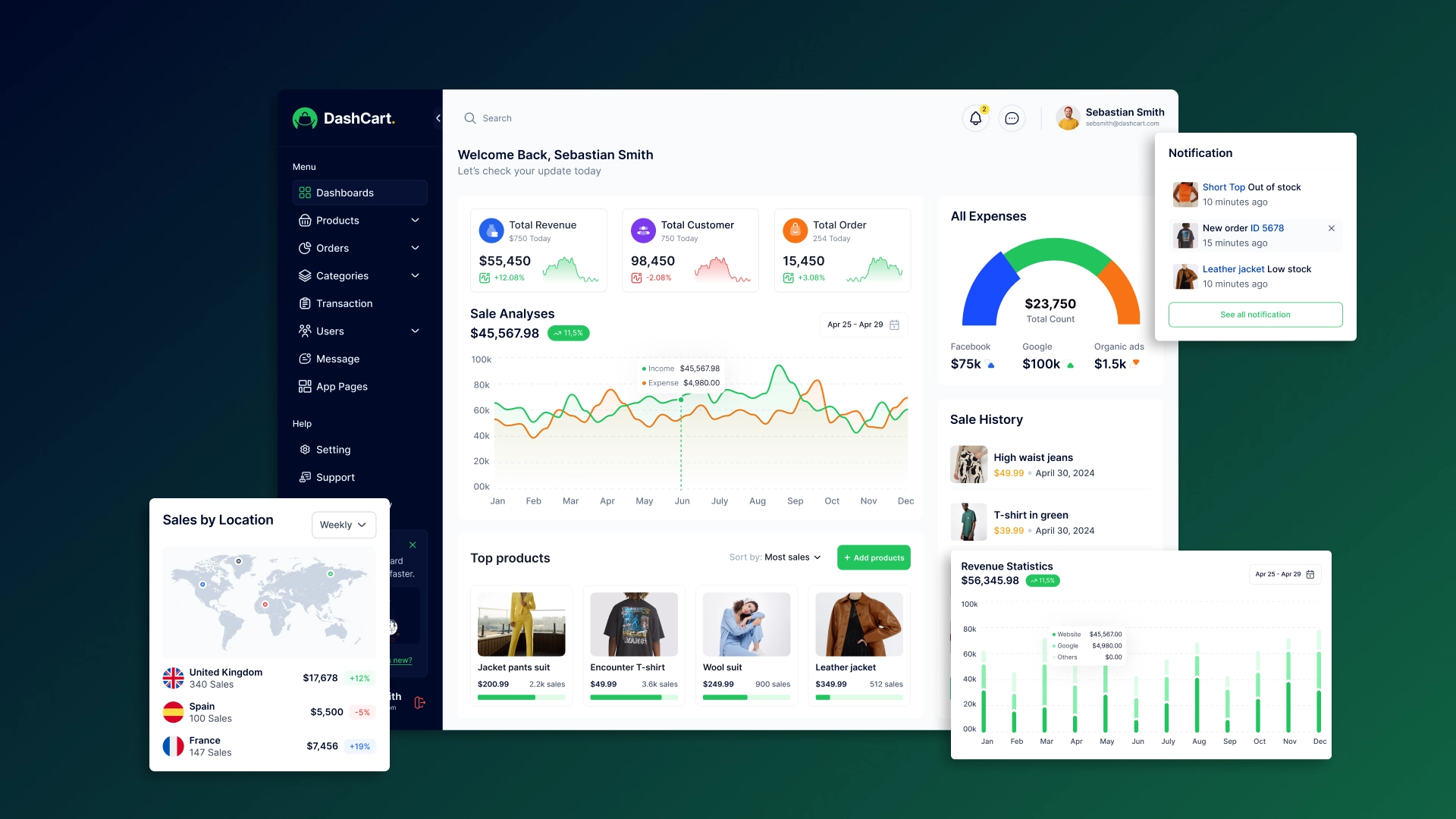

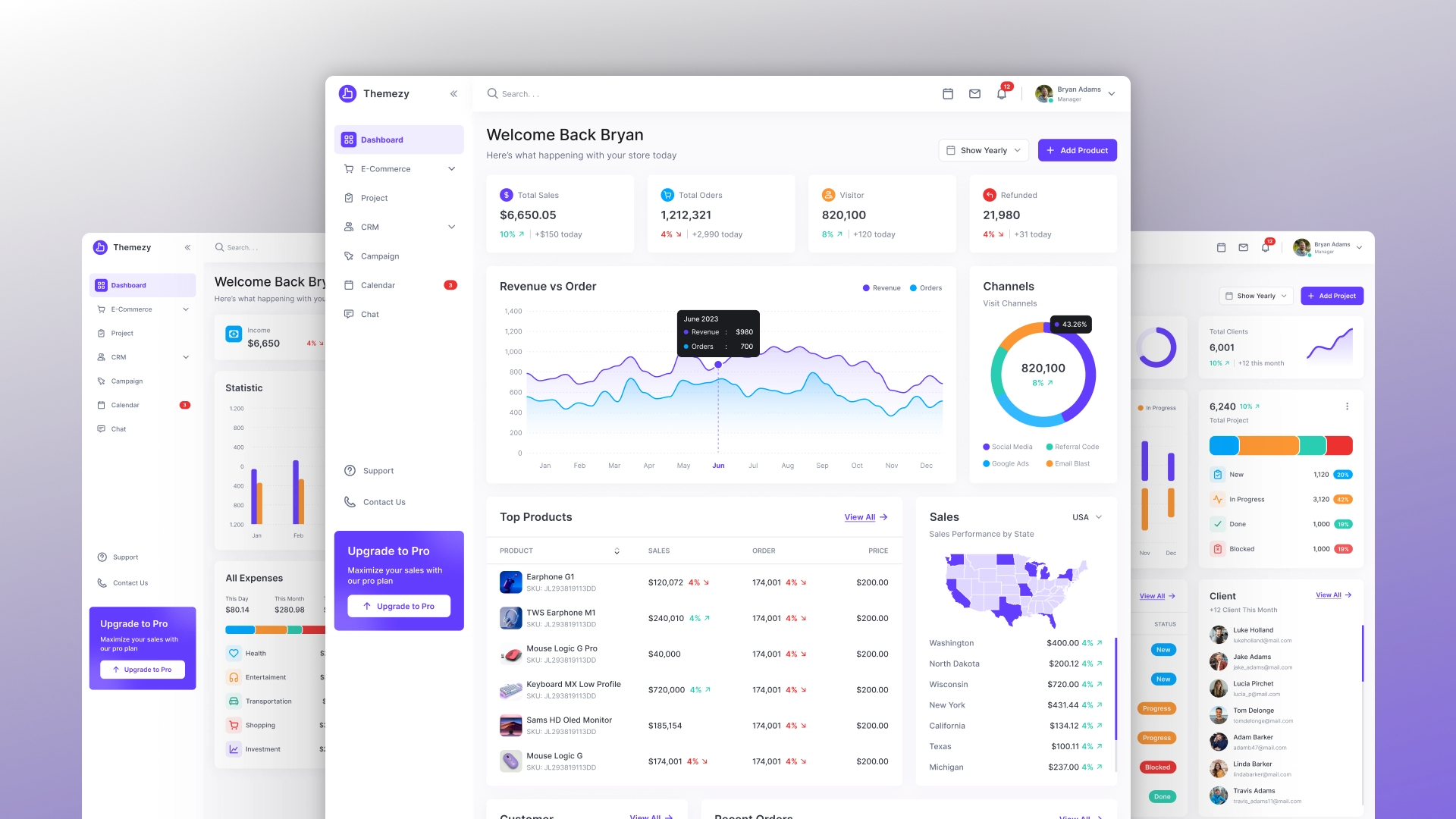

CRM systems

Improve interaction with corporate clients by providing centralized recording and analysis of data on sales, requests and customer preferences, which helps to increase the level of service and loyalty. CRM systems also automate marketing and sales processes, increasing the efficiency of the sales department.

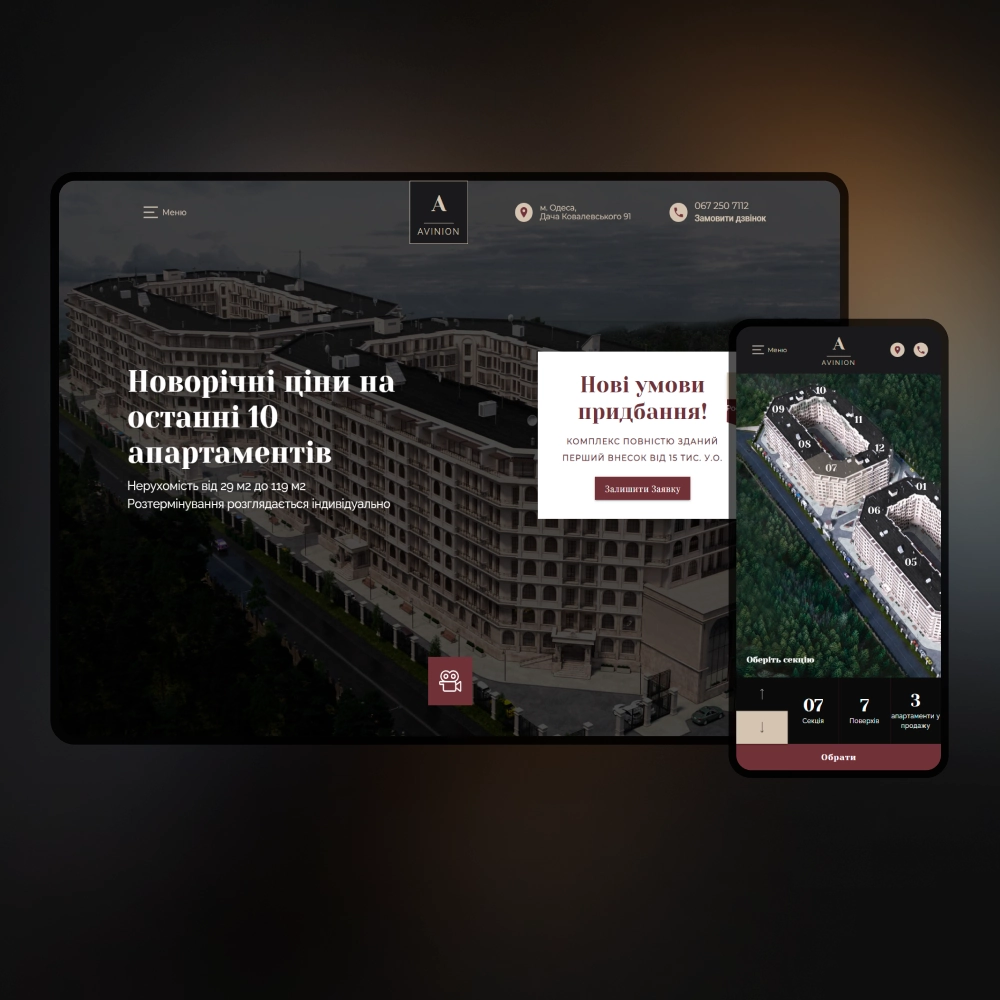

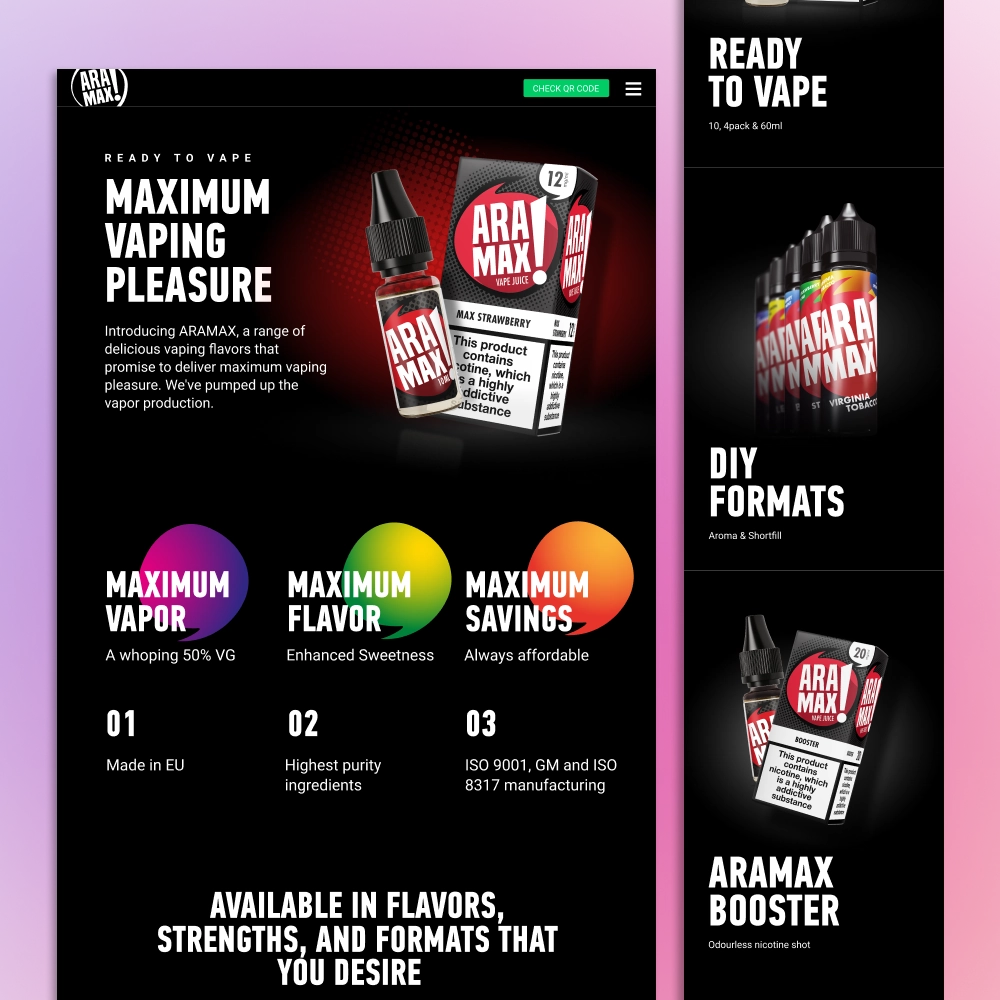

Corporate websites

A corporate website is the face of your company in the online segment. It allows you to effectively present products and services, and also provides access to important information to customers and partners, which helps increase sales and improve brand reputation.

WMS systems

Warehouse management systems optimize warehouse operations in an industrial enterprise by automating the processes of receiving, storing and shipping goods, which reduces costs and increases inventory accuracy. A WMS also improves inventory control and management by providing immediate access to raw material availability information to ensure production processes are not disrupted.

TMS systems

Transport management systems help optimize routing and transportation planning, which helps reduce transportation costs and increase the speed of delivery of finished products. TMS are also useful because they provide precise control and monitoring of cargo in real time, thereby increasing the efficiency of logistics processes and reducing risks.

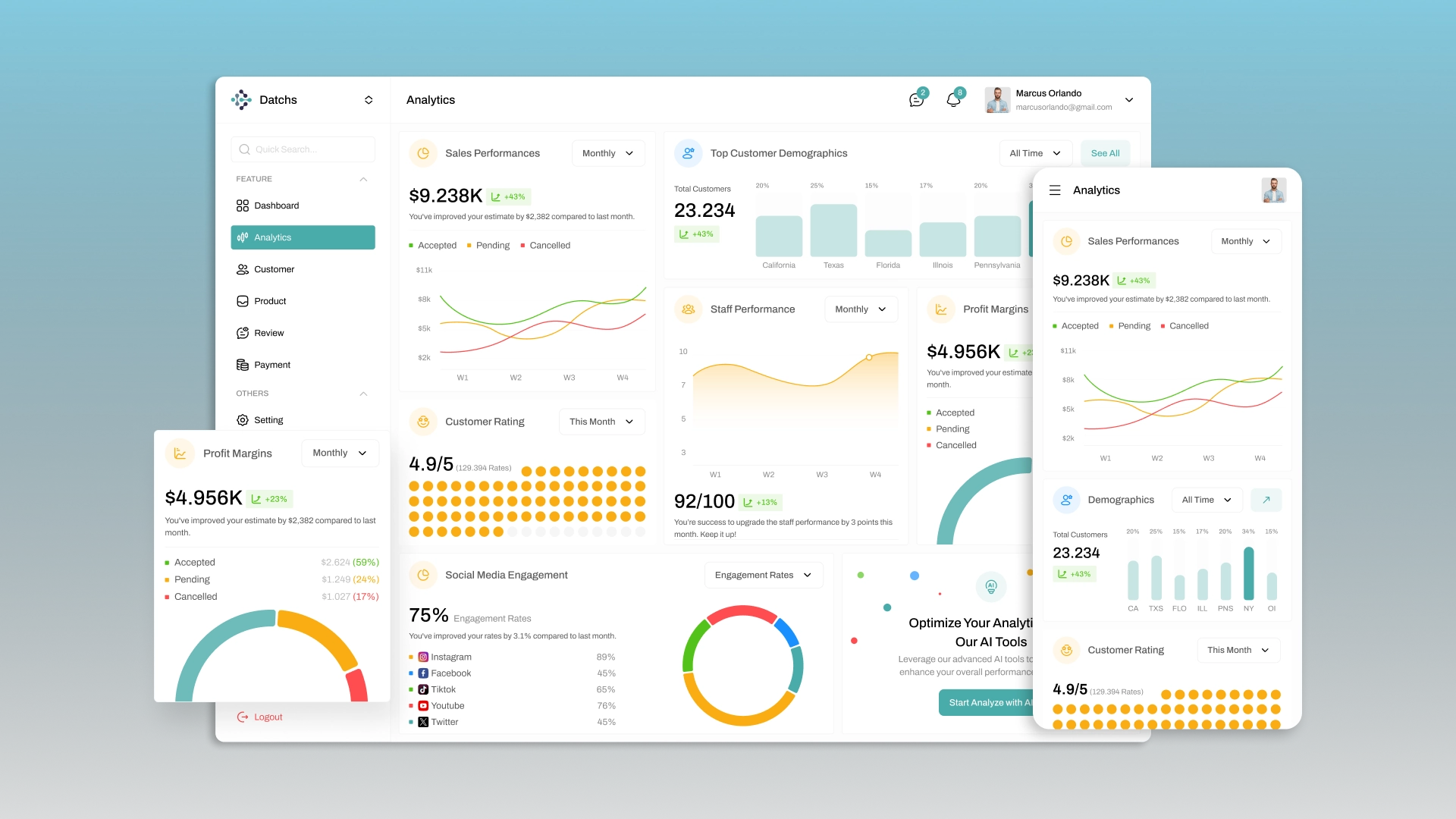

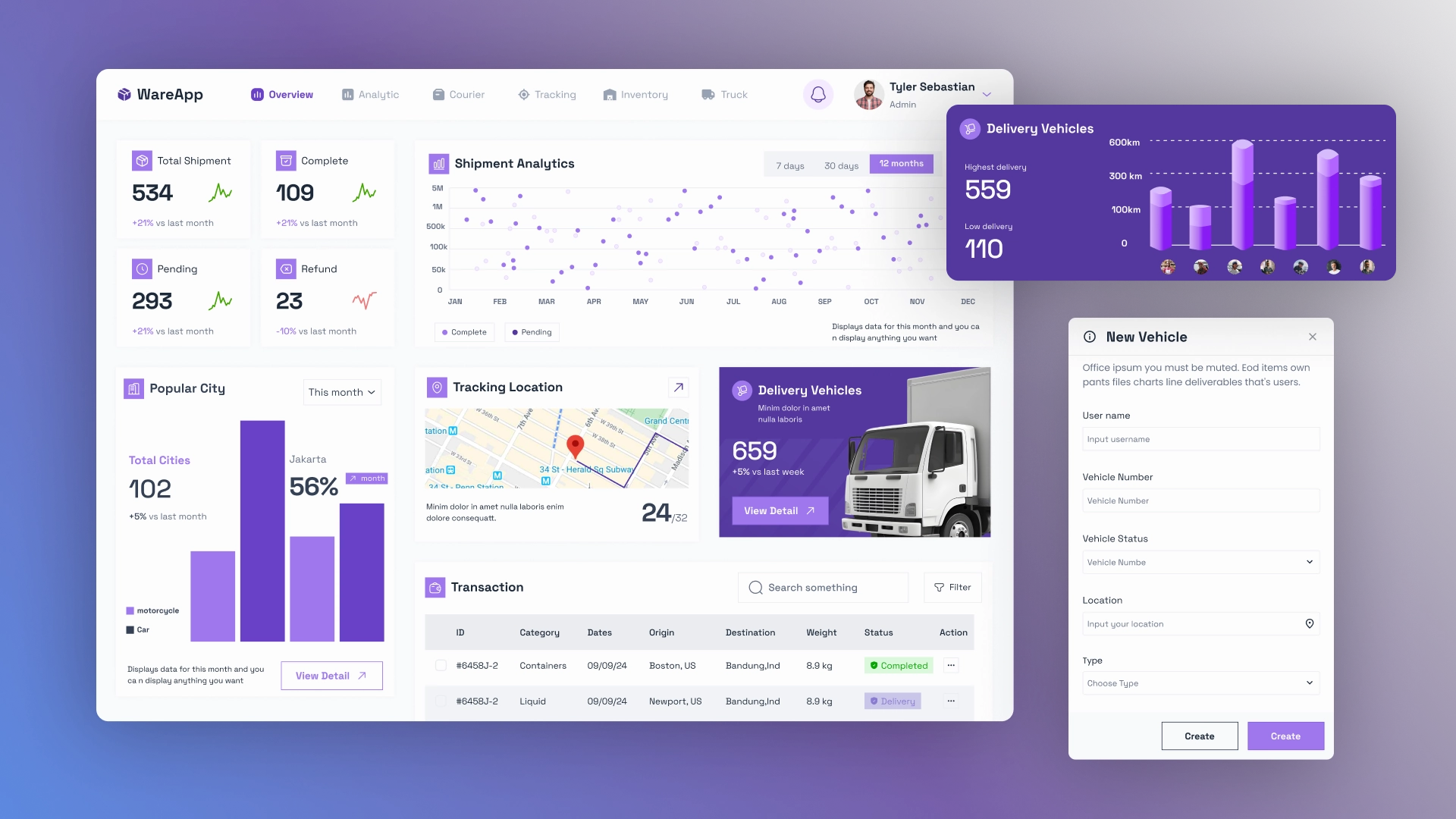

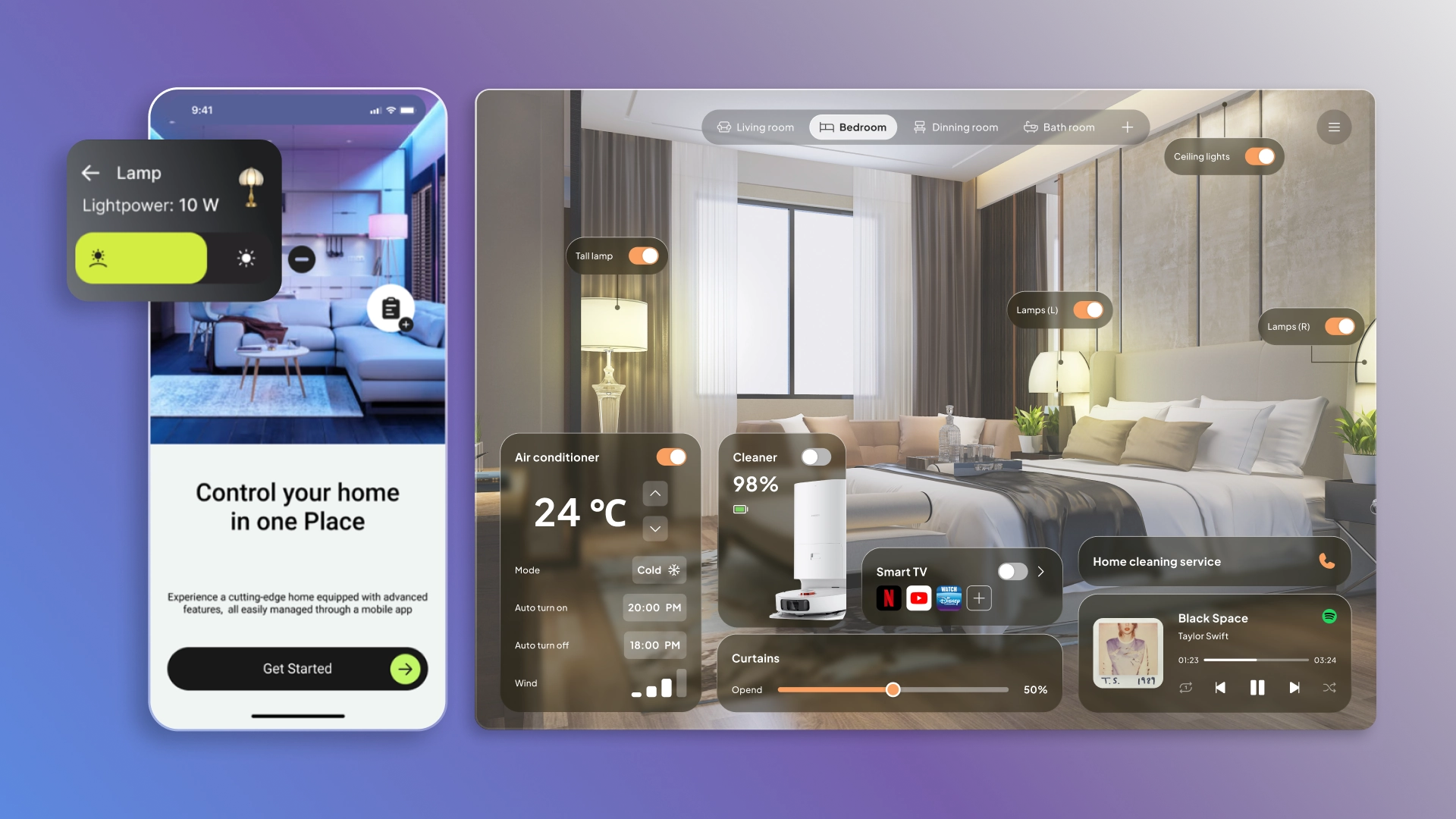

UI/UX Design

High-quality UI/UX design helps improve user interaction with the company’s digital products, making them intuitive and convenient. A well-designed interface also speeds up task completion, reduces errors, and improves overall employee efficiency, which helps speed up production processes.

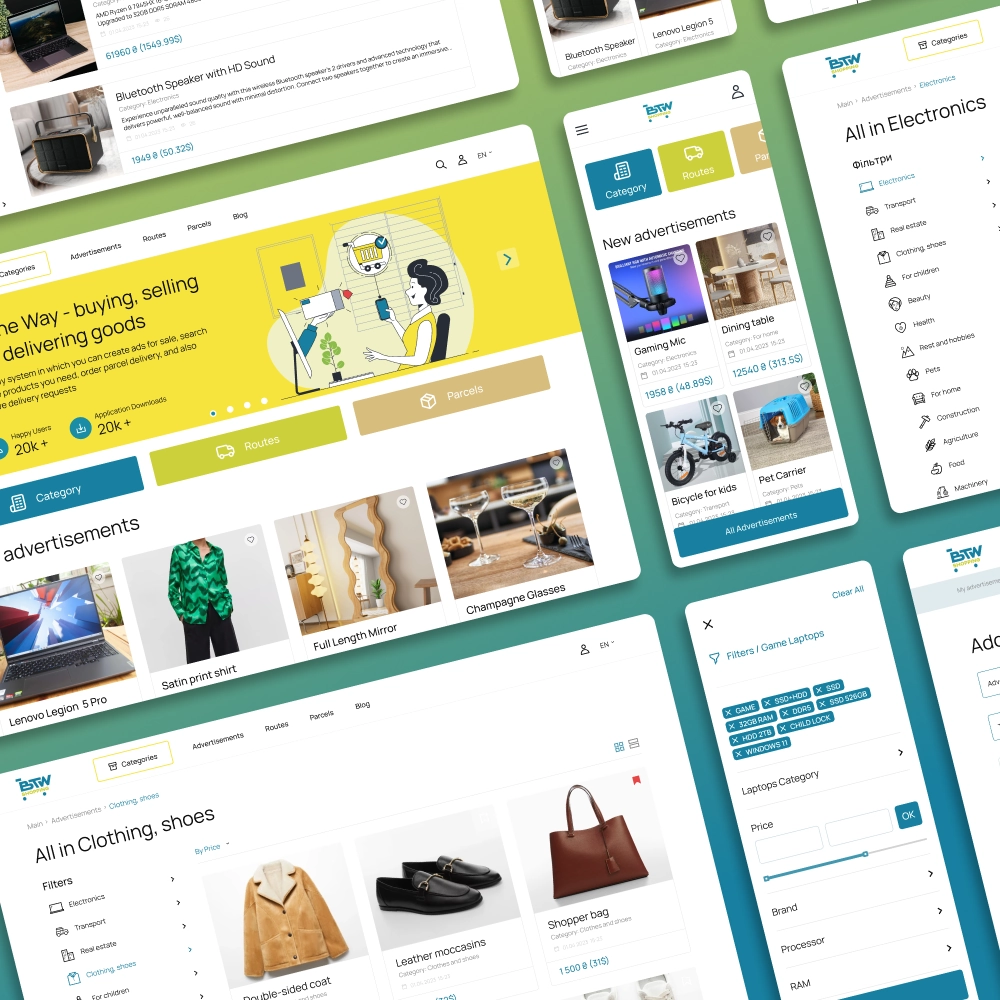

Online store

An online store allows industrial companies to expand their sales market and provides their customers with a convenient way to purchase products online. It also reduces the cost of maintaining physical retail outlets, provides round-the-clock access to goods and services, increases sales and increases the reach of the target audience.

Which companies benefit from custom software development for manufacturing?

All companies from different industries receive benefits from the implementation of innovative software, since the question here is not about a specific digital product that may be useful or, conversely, not useful for a particular business. We are talking about individual software that is designed and developed taking into account the needs of each individual company.

Here's how businesses across different industries can use manufacturing software:

- Mechanical engineering enterprises. Benefit from the adoption of digital solutions by automating production processes using MES systems, which increases efficiency and reduces costs. They also use predictive maintenance to prevent equipment breakdowns, which increases reliability and uptime.

- Food industry enterprises. May use various types of software, such as quality management systems to ensure compliance with product safety and quality standards, or traceability systems to manage supply chains and track the origin of ingredients.

- Chemical industry enterprises. Benefit from digital solutions that help monitor compliance with safety and environmental standards. In addition, they often use software to manage recipes and processes, which allows them to optimize production, reduce costs and improve the quality of the final product.

- Automotive industry enterprises. They use digital solutions to automate assembly lines and improve production accuracy. They are also implementing supply chain management and predictive analytics systems to optimize logistics and reduce service costs.

- Pharmaceutical industry enterprises. Use digital systems to efficiently manage clinical trials and track drug production, which helps ensure regulatory compliance, improve the accuracy of drug research and development, and improve inventory management and logistics.

Trends in Manufacturing Software Development

In the development of software for industrial enterprises, there are several key trends that determine the development and implementation of such software in different industries. These trends are helping manufacturing companies become more efficient, flexible and competitive, and include innovations such as:

- Cloud solutions allow manufacturers to securely store, process and manage data in real time, which increases the efficiency of IT solutions and reduces the cost of updating and supporting them.

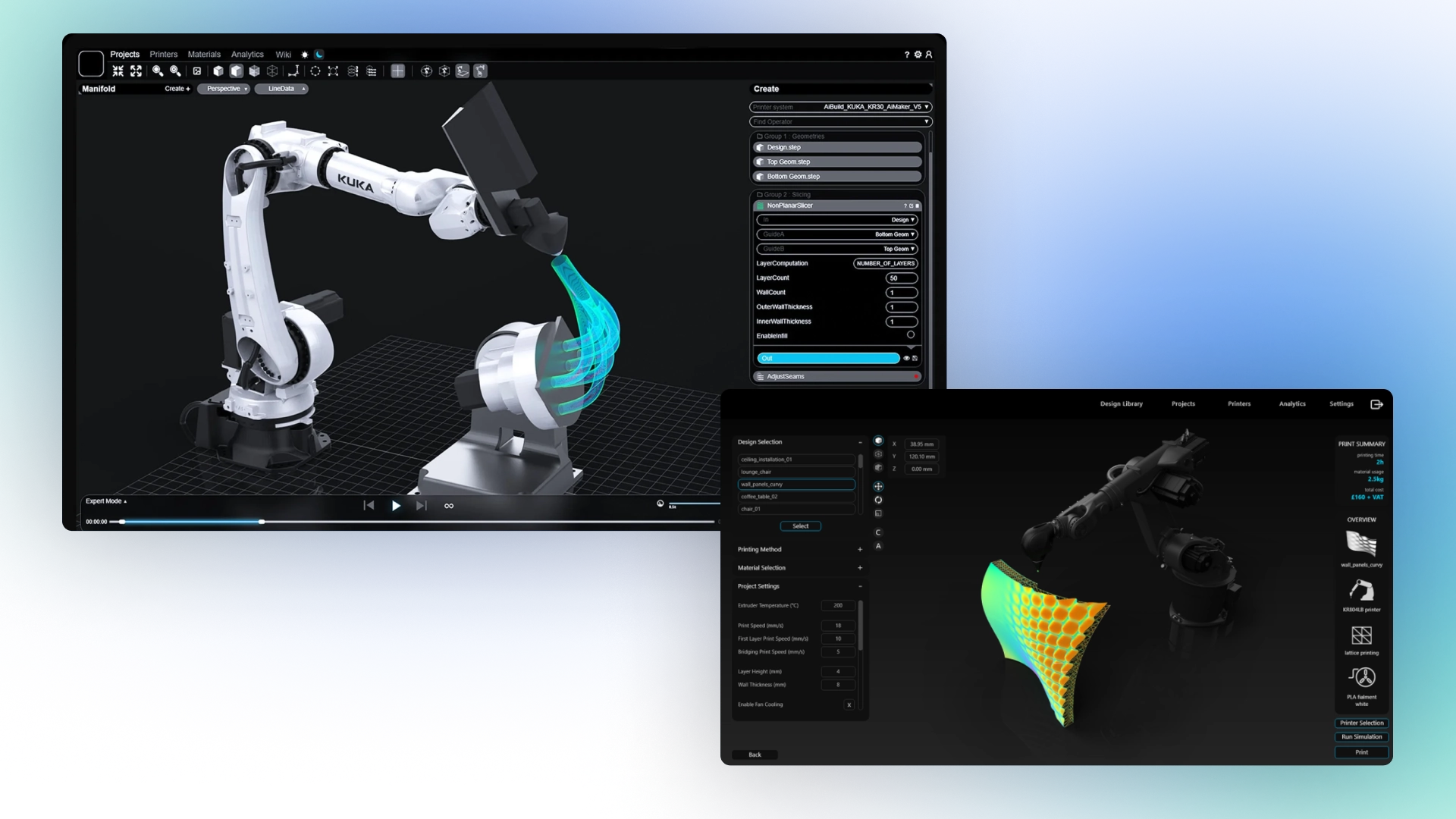

- Machine learning and artificial intelligence - used to analyze data and optimize processes, which helps reduce costs and increase productivity of production lines, as well as predict equipment breakdowns and prevent downtime.

- Internet of Things - connects sensors, instruments and other IoT devices into a single digital network that is capable of exchanging data without human intervention, which provides a high level of process automation.

- Blockchain is used to track supply chains and ensure transparency of transactions, as well as to verify the authenticity of materials and components, which increases trust in the products being manufactured.

- VR - virtual reality allows you to create virtual product models and immersive environments for design and production testing, as well as for more effective employee training.

- AR - Augmented Reality combines the virtual and physical worlds to visualize 3D product models in a real environment, which facilitates the design and decision-making process.

Stages of developing custom software for manufacturing companies

Avada Media's manufacturing software development services include several key components that ensure the creation of efficient and reliable systems that can meet the individual needs of each industrial company:

- Requirements analysis. Determining the needs and goals of the enterprise, collecting software requirements and analyzing current processes in the client’s company.

- Design and prototyping. Create visual mockups and interactive models that help clearly define the functional requirements of the software, as well as render user-friendly and intuitive user interface layouts.

- Development. Implementation of software modules and components at the code level, as well as integration of the product with external systems and databases to expand its functionality and ensure uninterrupted data exchange.

- Launch and development. The software is put into operation, after which the stage of its post-release development begins, which may include: monitoring system operation, quickly responding to failures, adding new functions and improving software performance.

Why choose AVADA MEDIA for enterprise software development

Software for production and industrial business management are complex and highly loaded systems that largely determine the success of the entire enterprise. With high expertise and a deep understanding of the industry, our specialists will help you design and develop a customized digital solution that fully covers your company's needs, and the use of innovative technologies such as IoT, AR/VR, machine learning and blockchain guarantees taking your current processes to the next level .

If you are planning to introduce innovations, or need help choosing software for your enterprise, contact us. We will definitely help you select and implement an individual manufacturing solution taking into account the unique needs of your business.